~ How CNC machining is used in the medical industry ~

The medical industry is one where there is a necessity for very precise parts and components within applications. Where life and death are very much part of daily life, and where failure of parts can have catastrophic consequences, the demands are high within any parts and components that are used within a medical application, and rightly so. This is where CNC machining comes in, offering unique capabilities that produce highly accurate parts that are required in bulk and at a fast-rate, always meeting very exact specifications for medical regulations. Essential equipment such as ventilators are needed quickly, and this is where CNC machining can be used effectively within the medical industry,

What is CNC?

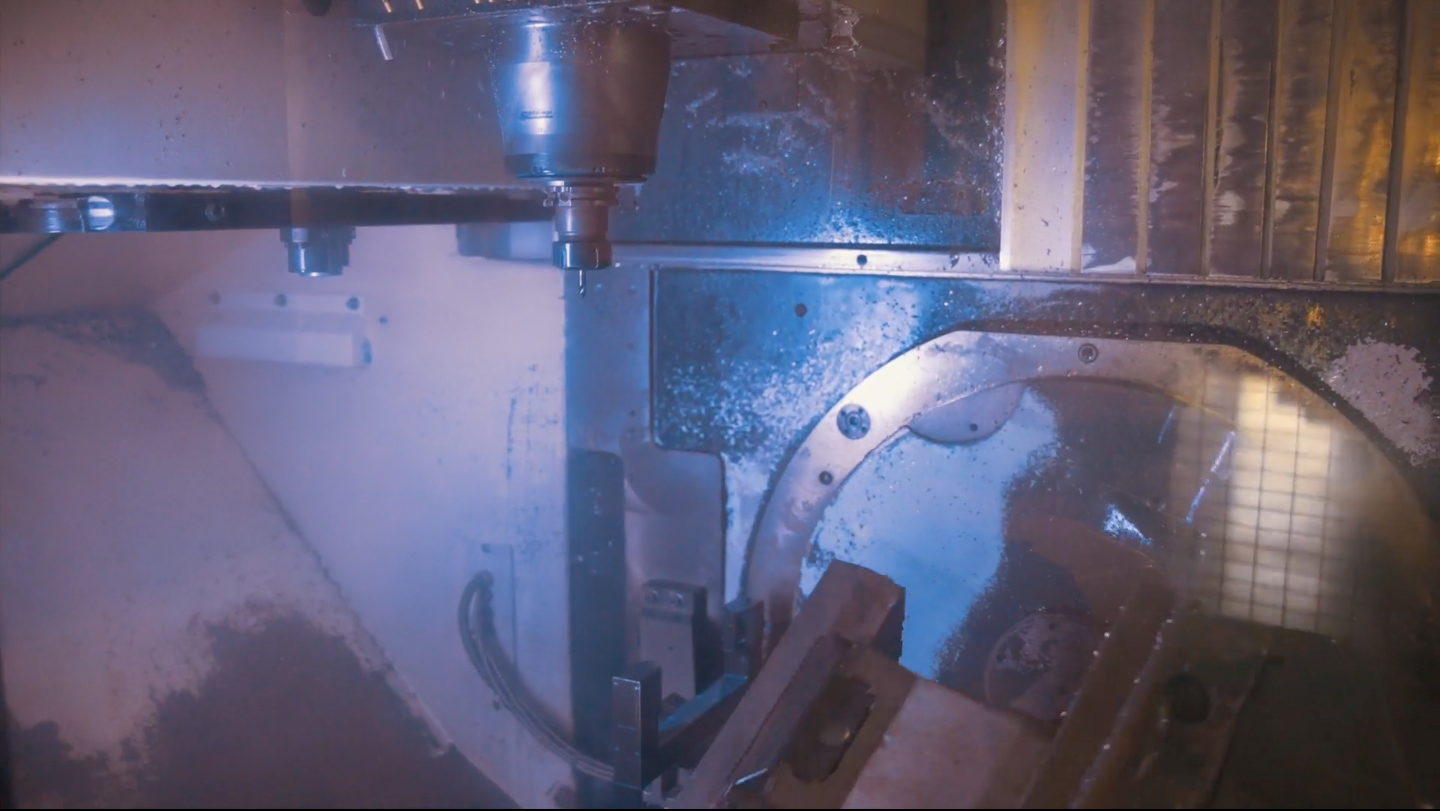

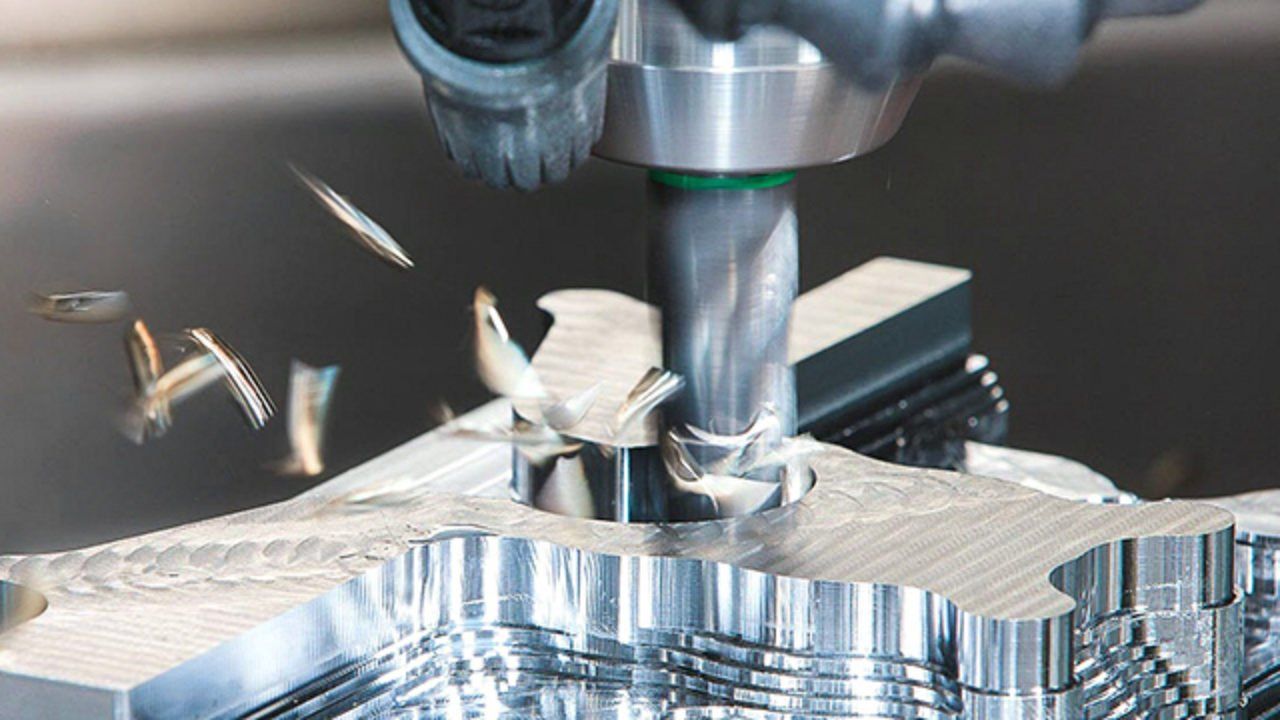

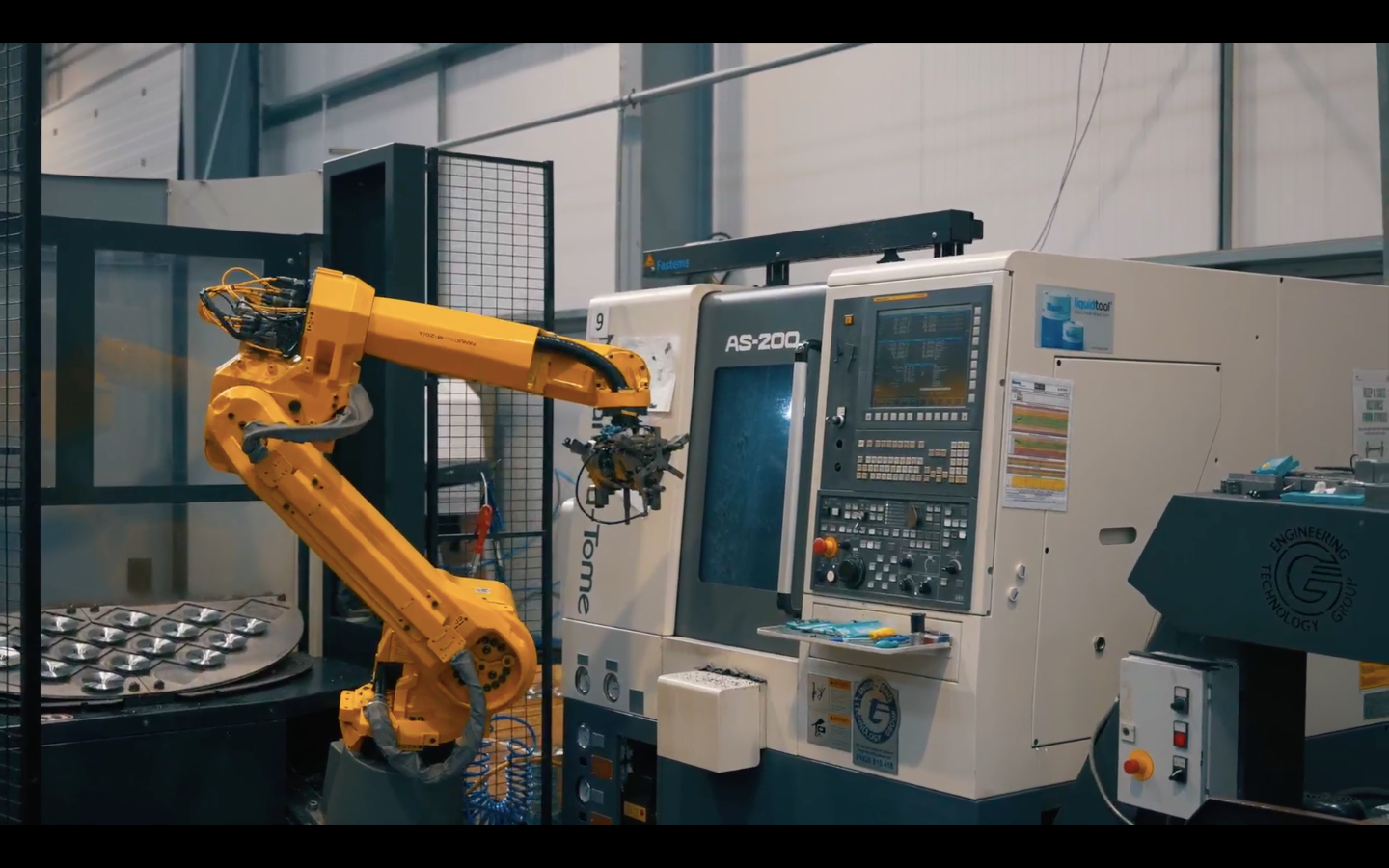

CNC machining is a subtractive manufacturing method that utilises Computer Aided Design (CAD) templates through an automated process. The machine follows a coded programme that eliminates the need for constant manual supervision and adjustment of the cutting tools to ensure that complex parts and components are efficiently created from raw materials. CNC machining offers greater speed, accuracy, durability and precision than other manual processes.

Why does the medical industry use CNC machining?

There are many every day, crucial applications within the medical industry that are made from plastics, metals, and injection moulding processes. Face shields, ventilators, and other much-needed equipment pieces must be produced in bulk, whilst maintaining precision and consistency to meet strict regulations and provide safe use in demanding medical situations and locations. CNC machines are the perfect tool to provide robust completed parts and consistency in production. As accuracy is a priority, and where even tighter tolerances are required, CNC machining becomes an important tool. This accuracy is why the medical industry has come to rely on CNC machining and its ability to provide such accuracy and uniformity for large-scale production runs for medical devices and parts of critical importance.

What materials are used within medical CNC machining?

Medical parts are designed with both disposal and sterilisation in mind, with specific tension and malleability requirements. Generally, the following metals are preferred within CNC machining for the medical industry, due to their heat resistant properties and durability:

- Nitinol

- Aluminium

- Stainless steel

- Titanium

What are the medical applications that CNC machining is used for?

There are many different types of medical applications, high-grade surgical instruments and components for a wide range of medical machines, such as pacemakers and ventilators, along with devices that are to be implanted into patients during surgery, that need to be produced to a high standard.

The three main categories of application that CNC machining is used for within the medical industry are:

Medical implants

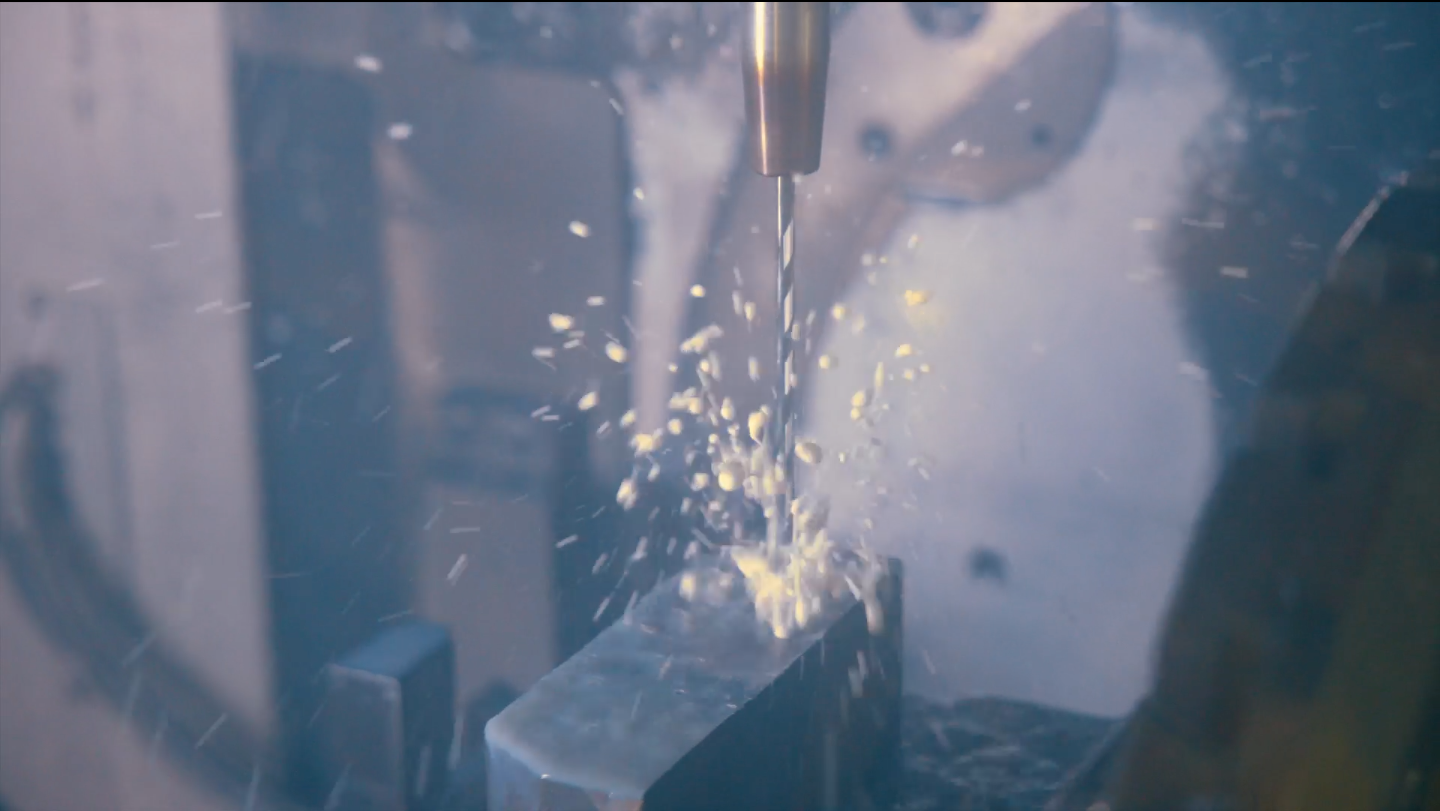

Implants such as a knee replacement need shaped parts that are unique, using titanium or stainless steel. Precision, accuracy, durability, and consistency are key where you are talking about something like bone screws that are to be used inside a patient’s body. To use this as a specific example, a bone screw could be as small as one millimetre in one direction, with the requirements of incredibly tight tolerances and a flawless surface finish in order to maintain patient comfort and to eliminate the threat of contamination. Stents and drug delivery systems, parts for implants and devices all require precision machining.

Surgical instruments

For surgical instruments there are a wide range of instrument types, from simple pieces such as surgical scissors, scalpels, retractors and forceps. These all require sharpness and reliability as key characteristics, as they are essential surgical tools that are used within important surgeries on a daily basis. Where accuracy and repeatability are required, CNC machining helps.

Parts for electronic equipment

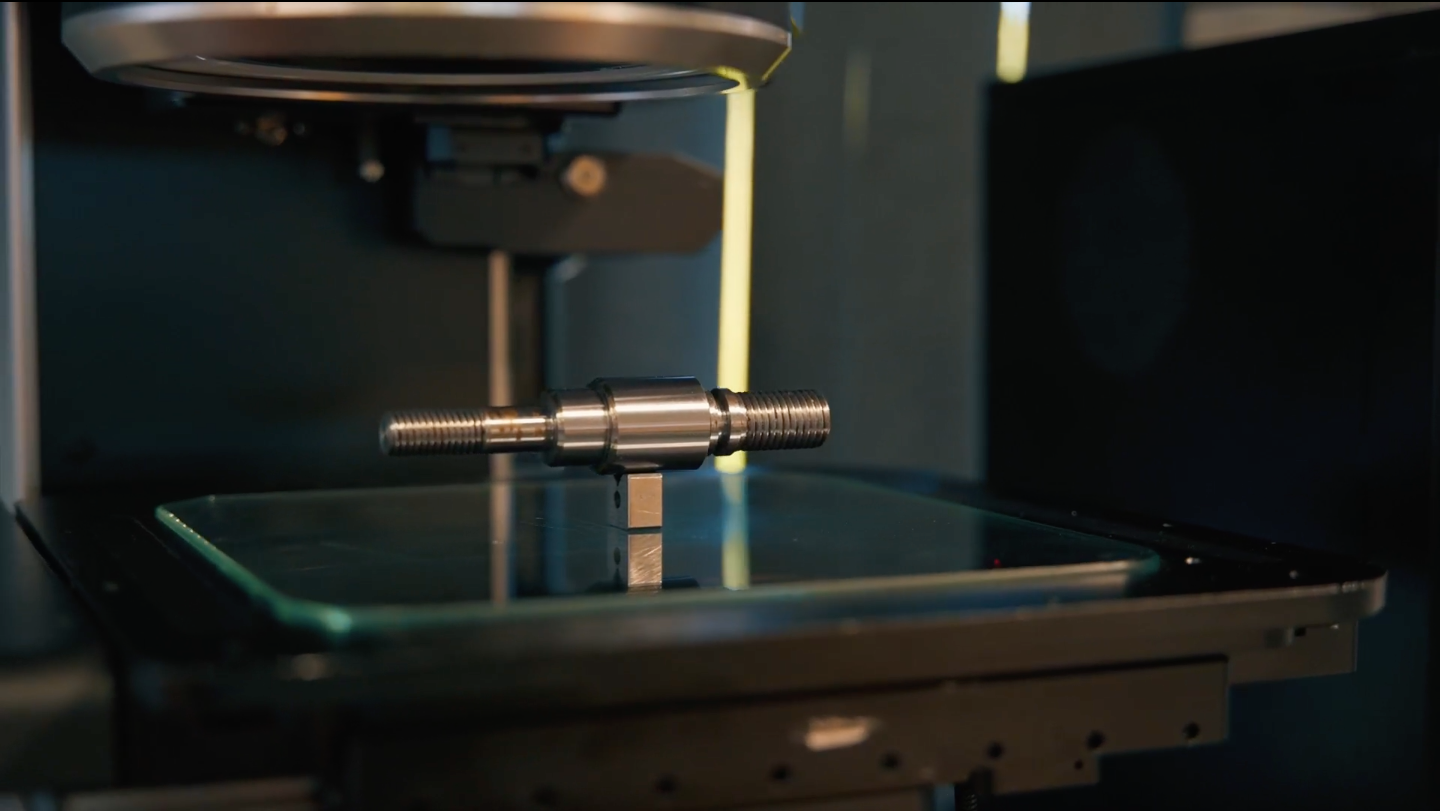

Complex electronic equipment such as X-ray monitors, MRI scanners, heart rate monitors and other vital pieces of medical equipment also require tight tolerances for components. These types of machines include thousands of fasteners, precision pins, screws and more. CNC machining provides this accuracy whilst also offering a wide range of potential finishes for a bespoke medical product to be manufactured.

What are the advantages of CNC machining for the medical industry?

CNC machining has changed the potential for medical devices, with incredibly small and precise parts and components now available for production on a mass scale. This type of accuracy and finish on such a scale can only be guaranteed through this type of manufacturing process, in most cases. Where a design would have once been too large, CNC machining allows for micro-machining technology to miniaturise components for a wide range of medical instruments and applications, whilst maintaining high standards of regulatory compliance. On top of this accuracy, pieces can be produced very quickly. CNC turning is used within medical research and development too, helping researchers to put together prototypes, with the production of small, crucial parts such as connectors for the biomedical industry.

What does the future of CNC machining for the medical industry look like?

The medical industry is constantly evolving, with innovation key to new medical techniques, medical equipment and instruments that will help improve the standards of medical care. The CNC machining landscape as it pertains to the medical industry will see some big changes over the coming years, with certain trends already in place.

Advanced materials

With the use of shape-memory alloys and bioresorbable polymers, there will be an adoption of advanced materials in the coming years, and CNC machining must keep up with the innovation to maintain high standards in creating parts and components for medical devices.

Combining with additive methods

Integrating additive methods of manufacturing, such as 3D printing, will add extra layers of flexibility to the approach in manufacturing medical applications. Combining both techniques will provide a better chance of maintaining high standards of production where complex and bespoke components are required that won’t be achievable with just one type of method.

Optimal AI use

AI is already being used in innovative ways to optimise production and this could be a key evolution in CNC machining for the medical industry. AI could be used to help identify ways to increase efficiencies and accuracy within the manufacturing of medical components, helping to save costs and increase productivity.

CNC machining for the medical industry provides great accuracy, durability, and precision in a constantly evolving and innovative industry that needs access to tight tolerances for components that are used in important devices, instruments, and medical devices.