~ CNC Machining Costs - A Guide ~

CNC machining can vary in cost anywhere from £10 to £21 when looking at a company in China, or closer to £30 in the UK (per hour). There are a few different factors that need to be considered when looking at the overall cost of CNC machining, whether you are looking for a single project or a long-term, larger production run.

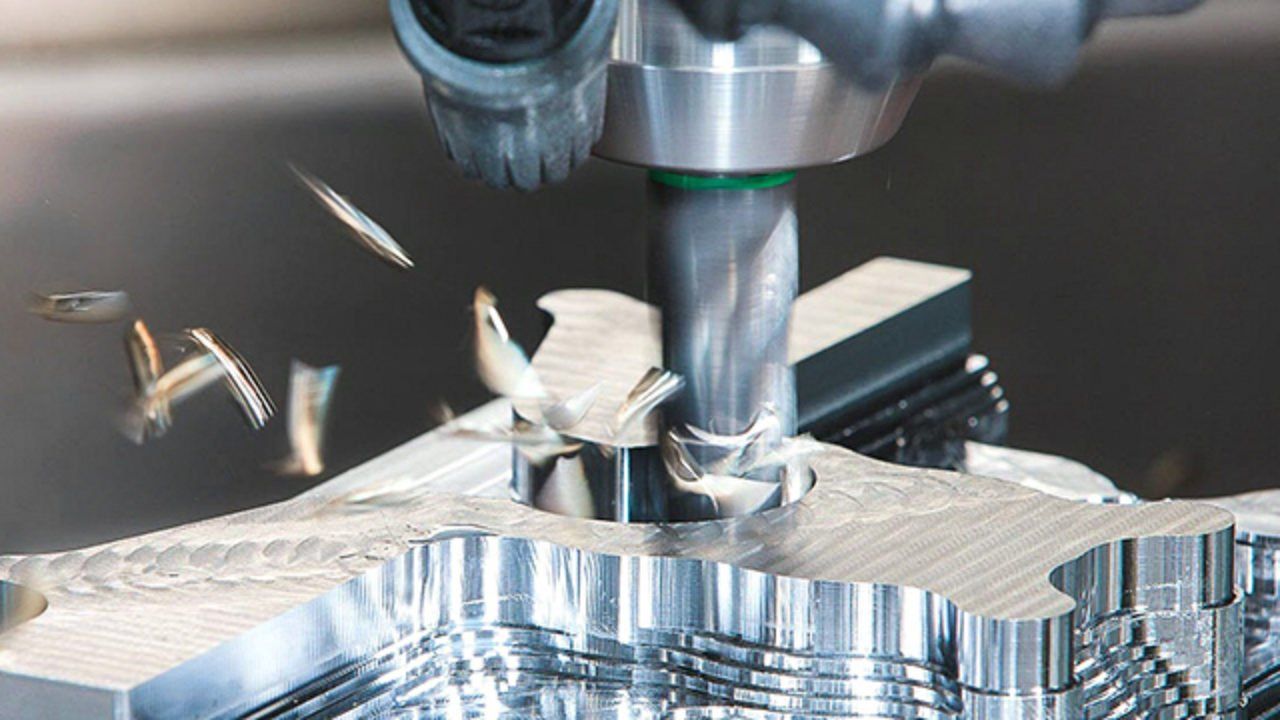

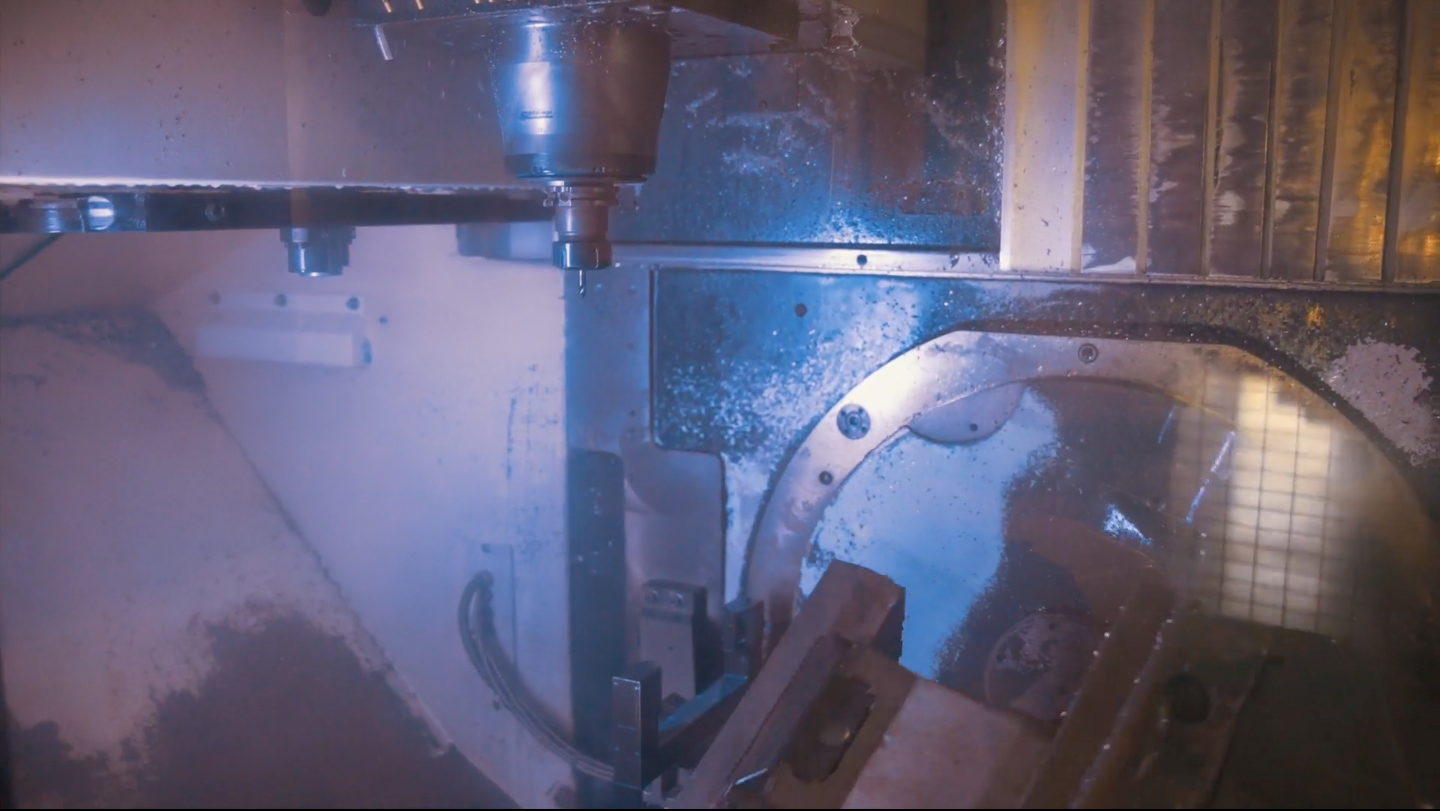

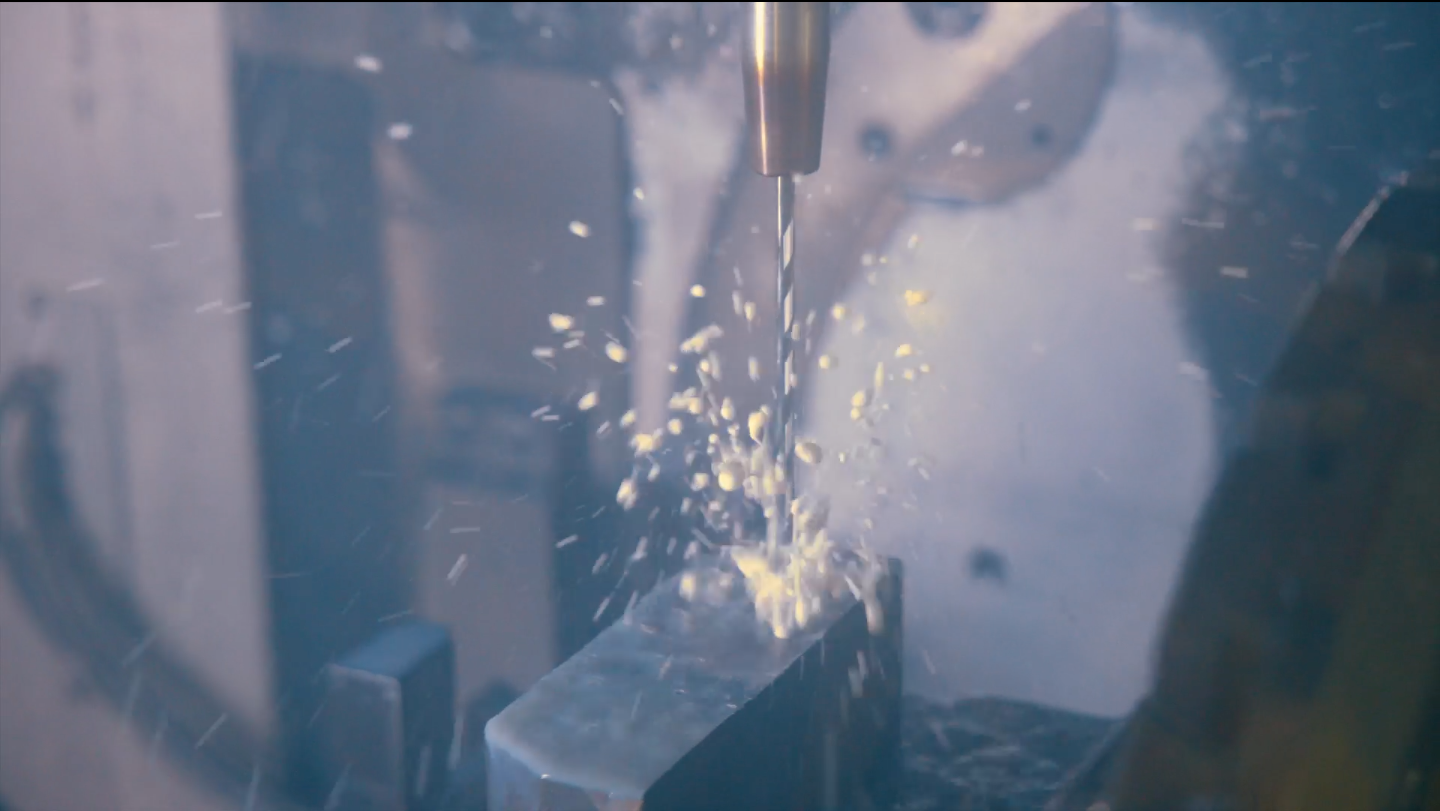

CNC machining is subtractive technology, requiring the use of both CNC milling and turning to cut away from raw material to create the desired shape. The main factors that help you figure out costs are labour, time, energy, as well as the design, the materials being worked with, and the quantities required for the production run.

What to consider when buying a CNC machine

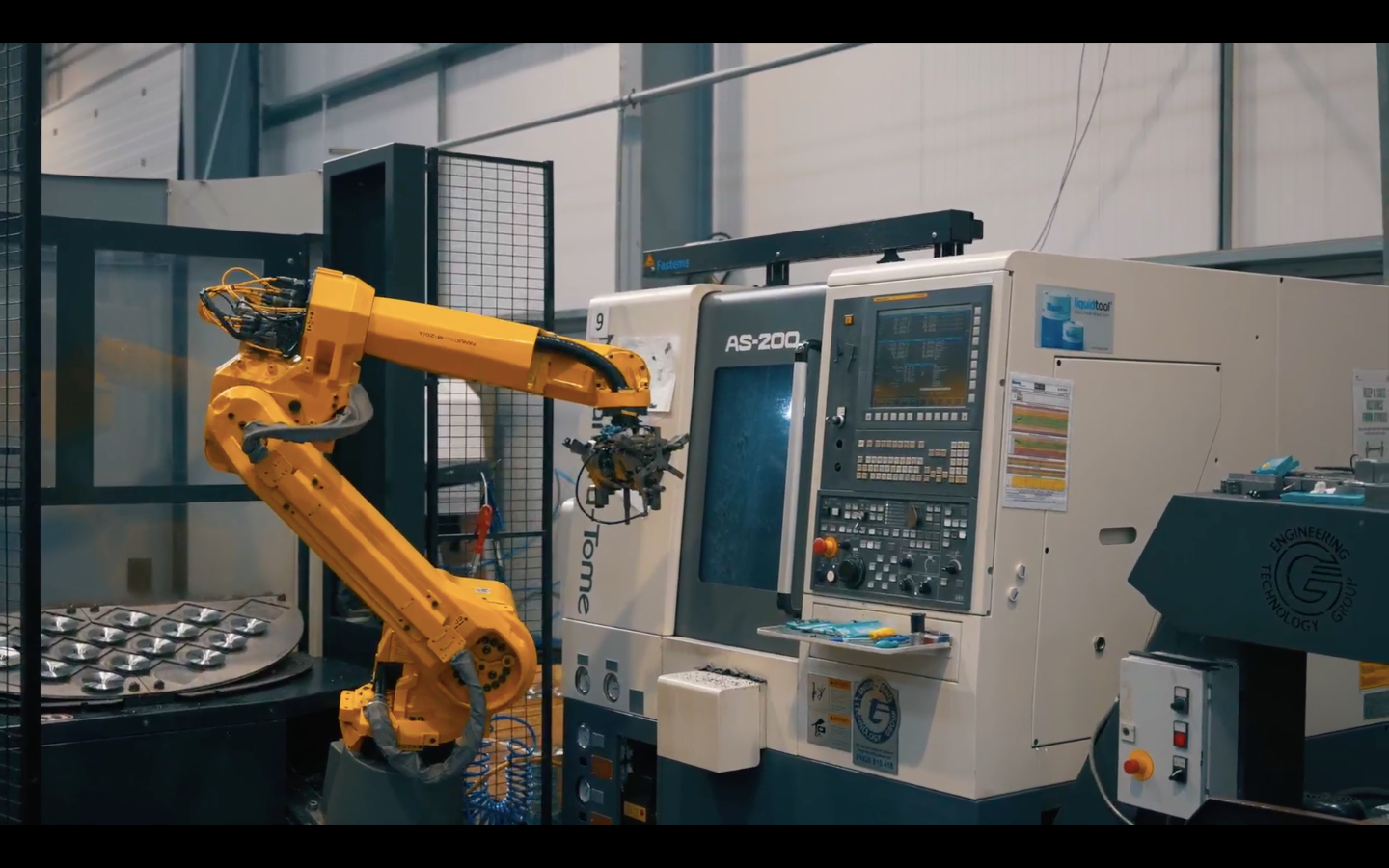

There are a few things to consider when buying a CNC machine. First, think about the specific needs of your company in terms of the projects you have coming up and the materials that you’ll be using. How much space do you have to work with? What budget do you have, and what are the technical requirements of your projects? In some cases, you might need just a short, single production run of a simple piece, or a longer production run with a more complex end product desired. All of these things will factor in when deciding on the type of CNC machine you require.

Different types of CNC tools

The machining process is different depending on the CNC tools you are using, and this will impact the cost. These include:

CNC laser cutters – This is where a high-powered laser is used on a variety of materials, including wood, acrylic, copper, and metal.

CNC waterjet cutters – Using a high-pressure water stream that is combined with abrasive particles, even difficult materials can be cut through.

CNC routers – This cutting tool uses rotation to carve out designs and shapes across a wide variety of materials, such as wood and acrylics. Routers help you to achieve sharp edges and tight tolerances.

CNC milling machines – Rotary cutting tools are utilised to remove material from the workpiece, and this can be achieved through tapping, cutting, and drilling. The perfect tool for complex shapes.

CNC plasma cutters – A high-velocity jet of ionised gas is used to cut through metal. This is a tool frequently used within the automotive industry and in businesses where metal fabrication is required.

How much do CNC machines cost?

There are many factors in play to determine the cost of a CNC machine.

Size of the machine – The size of the machine is important in determining the cost. CNC machines come in a wide variety of sizes, from small machines that can fit on a single tabletop, to large machines that are so big that you could drive a truck into the work area of the machine.

Types of CNC machine – Depending on the configuration of the CNC machine (3, 4, or 5 axis), the cost will be higher. This is because the more axes present on the machine, the more powerful it becomes, and the complexity of potential geometries increases too. There are different types of CNC machines, from lathes and milling machines to plasma cutters. Each has its own price range, with a basic CNC milling machine costing between £15,000 and £40,000 typically, and a high-end machine being sold for £150,000+.

Power and speed – The more powerful a spindle, or the higher RPM a spindle can reach, the greater it enhances the potential of the CNC machine. Accuracy combined with high speed, this makes the CNC machine much faster in production rates, which adds to the value and cost of the machine.

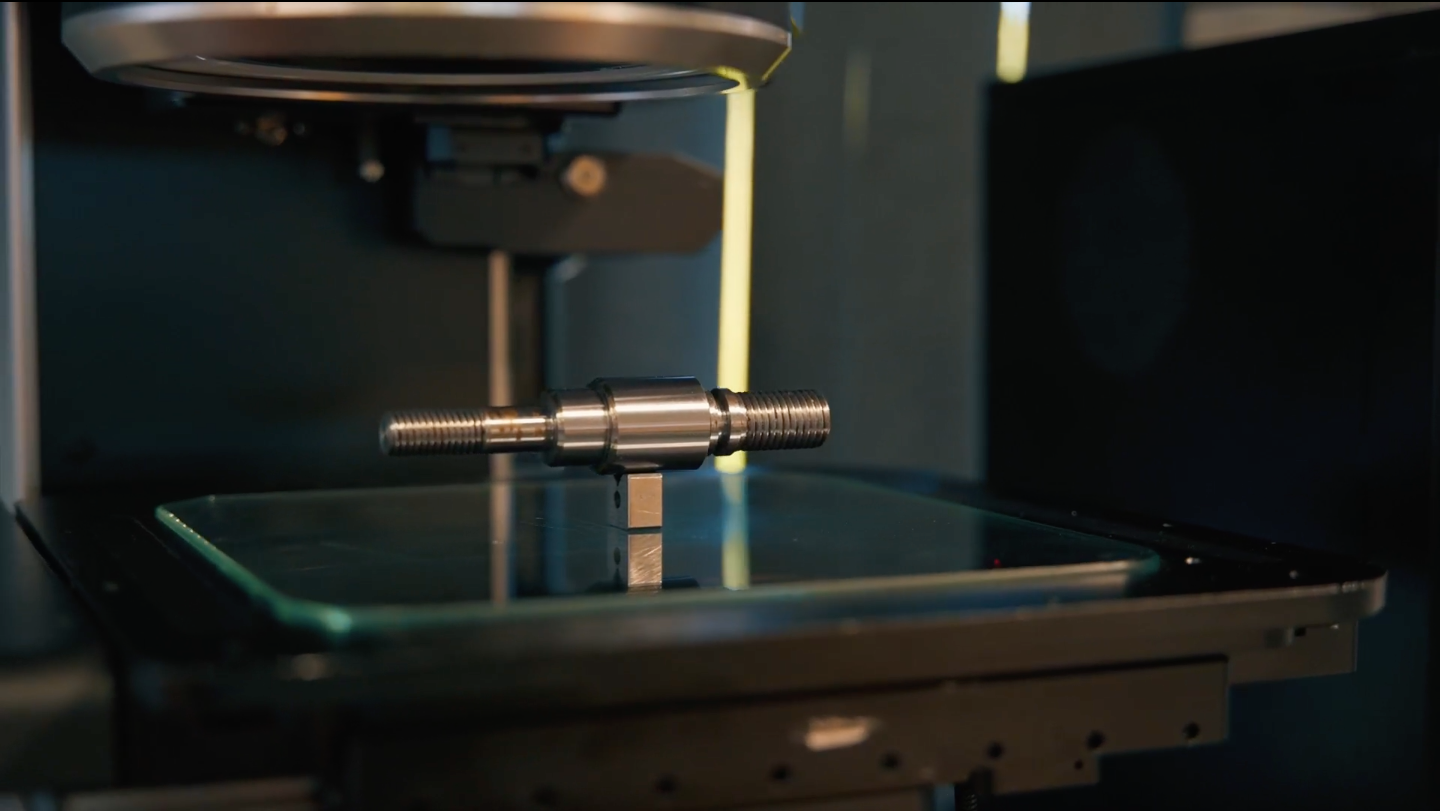

Accuracy and tolerance – Tolerance and accuracy are two words that are vital within the world of CNC machining. The higher the guarantee of accuracy and the tighter the tolerance, the higher the cost of the machine.

Brand and manufacturer – There might be a higher cost in choosing CNC machines from a reputable brand with a reputation for reliability, but in these instances, it is less likely that you will be paying out for maintenance and repair issues, and that the lifespan of the machine will be much longer.

The upfront cost of a CNC machine might be considerable, but when you consider the long-term benefits of accuracy, reliability, and efficiency, it can be a cost-saver in the long-term to work with CNC machines. When working with a reputable CNC machine servicing company too, you can minimise downtime through regular, extensive inspection, maintenance, and repair where necessary.

What other costs do you need to consider?

There are other costs that you need to consider beyond the CNC machine itself. This relates to a wide range of things, such as:

Site preparation – Ensuring the machine is delivered and installed in the correct location and in the best place logistically for the production runs you have planned, is an important part of the process, and there could be costs attached to this. For instance, if you are purchasing a large, heavy CNC machine, this might require a greater number of people for the ‘rigging’ process to get it into place.

Tooling requirements – The CNC machine will require tooling and consumables, such as coolants and lubricants, before any production can commence. The specific cutting tools for the tasks ahead must be purchased and installed too.

Inspection tools – You will require inspection and measuring tools no matter what, but the higher the precision in play, the more accurate these tools must be. A CNC lathe or milling machine might require greater detail here, whereas a plasma table, router, or laser machine might not need as much.

CNC software – This is one of the most important support investments you’ll make for your CNC machine. The digital tooling and suite of software will shape how your projects go in many ways. Computer-aided design (CAD) will be the least you need, along with CAM software, feeds and speeds calculator, and potentially a CNC control system.

As you can see, there are a whole host of things that you need to consider when looking at CNC machining costs, whether you are looking at production of a simple component or many complex parts.

Rotec Aerospace Limited, Enterprise Way, Vale Business Park, Evesham WR11 1GS United Kingdom

Phone: 01386 424111

Email: Info@rotec-ltd.com

Office Hours :

Mon-Fri : 7:30am - 5pm