Oil & Gas CNC MACHINING

The oil and gas industry requires well-manufactured machine parts that fit perfectly together and ensures a safe and pristine working condition at all times. Without this precision engineering, a part might fail, causing a leak or other fault. Oil and gas CNC machining services from Rotec delivers carefully manufactured, precision parts and components for the industry, ensuring that rods, valves, pistons, pins, cylinders, and drill bits are readily available with consistency. This helps to ensure a high level of safety and consistency on site and minimises downtime should any parts fail, and a replacement is required.

Contact Us

Get in touch here

Certified Oil & Gas CNC Machining

The oil and gas industry operates within often harsh conditions and remote locations. That is why it is so important that crucial components and parts are manufactured to such high and consistent standards, as there could be the need to replace parts on site without damaging projects and timescales. Rotec is an industry-recognised leader in producing components for the oil and gas industry with our top-notch CNC machine services. Robustness and precision are key for parts manufactured for this sector.

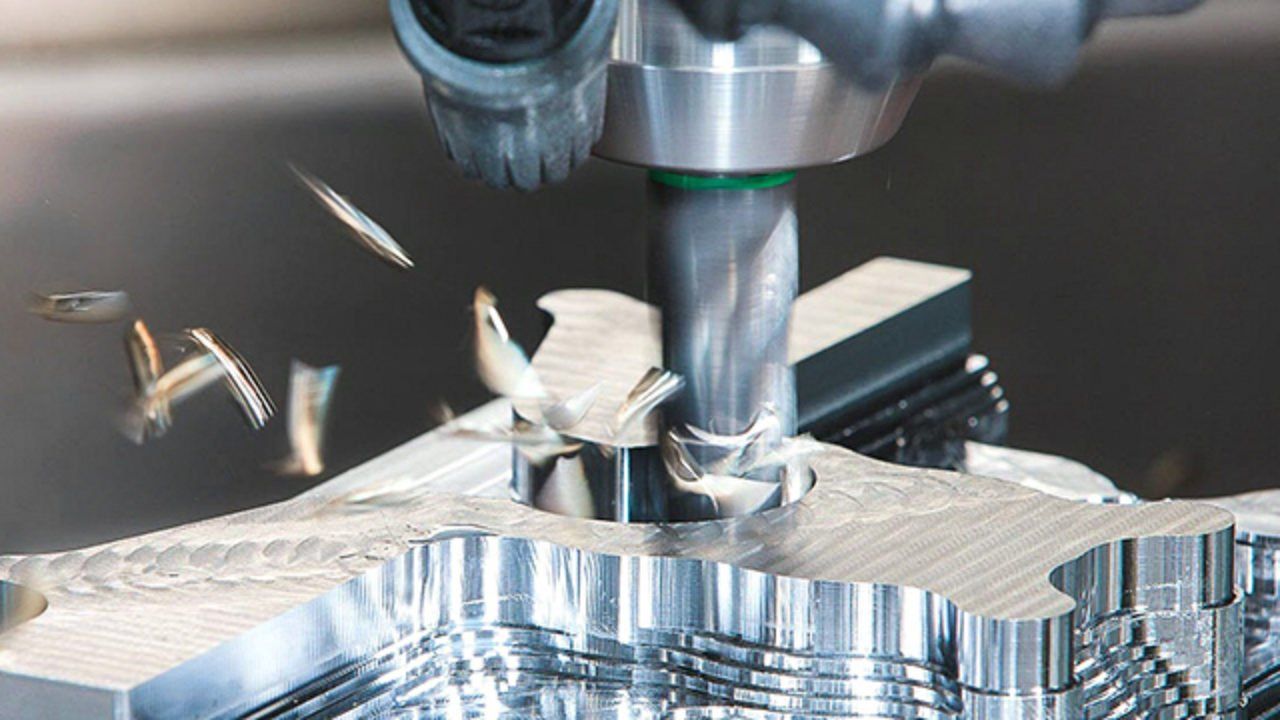

Oil & Gas CNC Machining Services

Our use of sliding head lathes ensures that cycle times and costs are significantly reduced. Achieving up to 39 machining positions with 8 axes, often a component can be completed in one single set-up, improving efficiencies.

Our team continues to refresh our fleet of machines, investing significantly in our Turning and Mill/Turn technology. This allows us to remain ahead of the game, providing a tailored service and solution to our customers that is hard to match within the industry.

We continue to innovate, refining our 5 axis CNC machining services for maximum output at reduced time and cost. The 5 axis provides you with the power and precision for myriad uses, maintaining accuracy and delivering consistently.

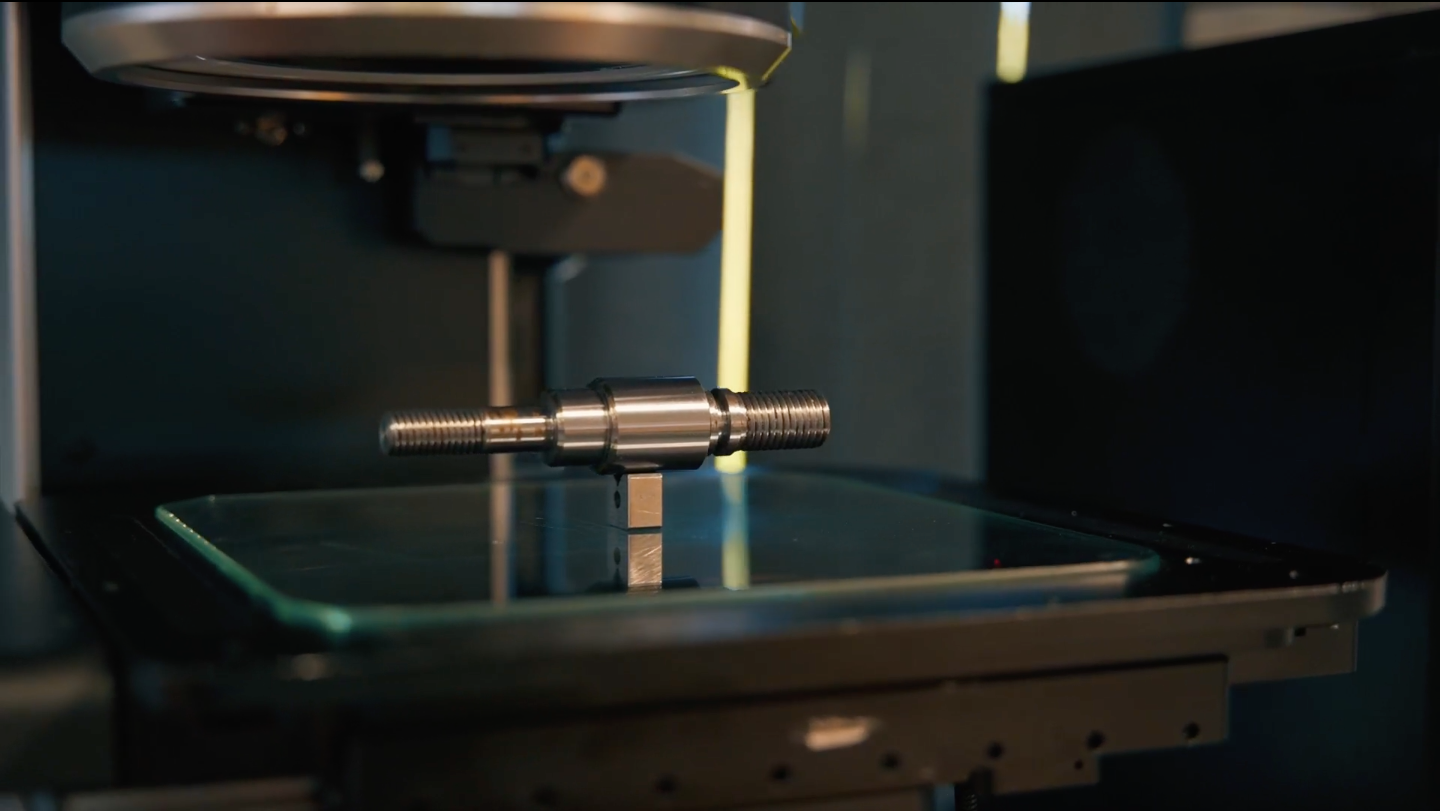

CMM inspection is another service Rotec offers to boost the accuracy and consistency of manufacturing processes. It involved precision CMM inspection services that takes CAD models and 2D drawing formats and provides a detailed report tailored to each client and process.

Customer Focused

We make sure our customers are incredibly satisfied with every order, we hold a large repeat customer base and some of our clients have been with us since the beginning.

Expert Team

Your project will be handled by professionals who care. We make sure you have a dedicated team working for you.

Quality Assurance

Get the support you need to ensure that things runs smoothly. We’re here seven days a week to answer any question.

24hr Automated Facility

We have an automated 24 hour facility and professional team to support you at all times from Mon-Fri: 7:30am - 5pm

Material We Work With

- Aluminium

- Stainless Steel

- Titanium

- Mild / Carbon Steel

- Brass / Copper

- Nickel Super Alloys

- Many more…

If you have a specific material that you would like us to work with, please Contact Us

Our Oil & Gas CNC Machining Company

The Rotec team understands what it takes to deliver precision, robustness, and consistency of delivery when it comes to manufacturing components to be used within the oil and gas sector. We are constantly striving to improve our services, investing in the latest technology and the education of our team to ensure that what we deliver to our customers matches their exacting standards. This is no more so than in the oil and gas sector where there are harsh climates to endure and risks to avert.

Contact Us

If you're a potential client and have a project we can discuss, our journey together begins here. Fill out the form and we'll be in touch or use the contact details below