Cnc turning

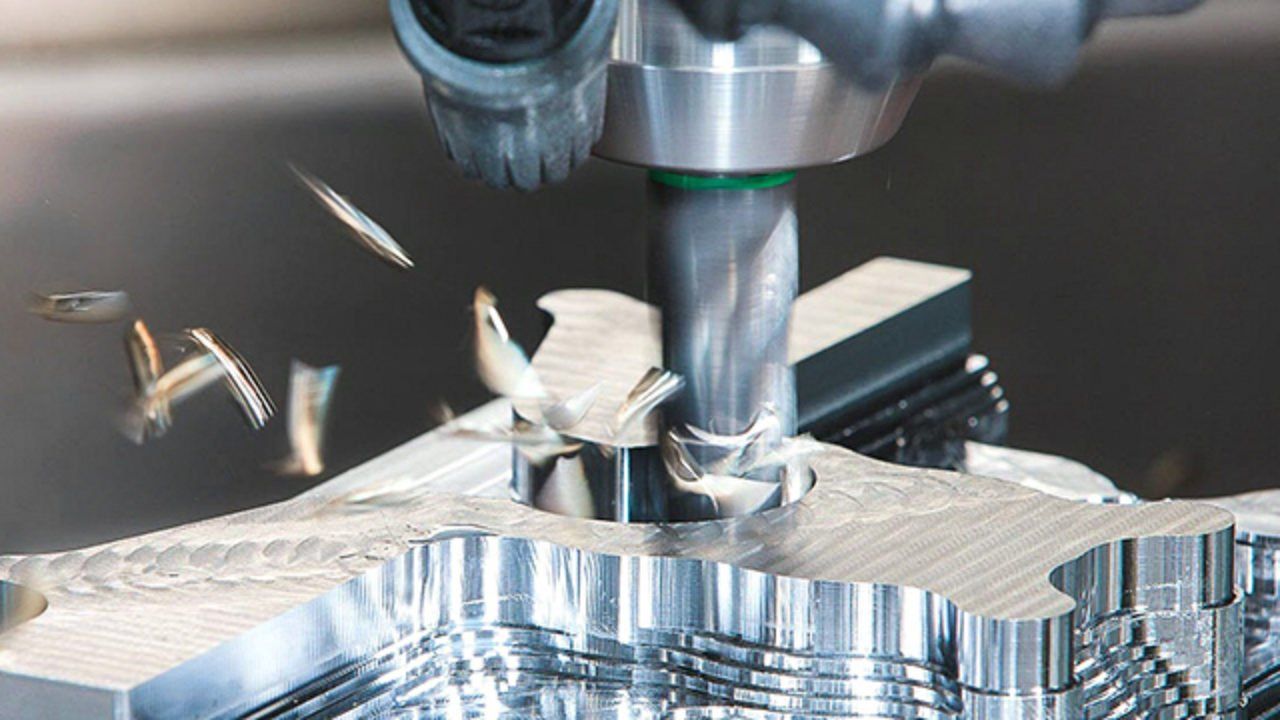

CNC Turning Department

Rotec has invested heavily in our CNC Turning services in recent years. This allows us to refresh our fleet of machines and to keep the standards high. The latest automation solutions provide flexibility within our Advanced Manufacturing Centre, providing a larger capacity and a bespoke solution to our customers. Our CNC Turning capabilities allows for production of short and long batch runs, servicing myriad sectors and working with many different materials, component footprints and complexities, for the most rigorous of requirements.

Contact Us

Get in touch here

Expertise

High volume small turned parts

Low Volume Prototype Batches

Die Making Consumables

Bolts and Fasteners

Heatsinks

Gear Cutting / Hobbing

Shafts & Pins

Aerospace Components

Our CNC Turning Machines

Our CNC turning service provides a bespoke service and solution to customers. We strive to refresh our fleet of machines and invest in turning and mill/turn technology to stay ahead of the game.

dmg MORI NLX 2500 / 700 X2

The NLX 2500 is a high-performance CNC lathe designed for precision turning operations, commonly used in industries such as aerospace, automotive, and medical device manufacturing.

nAKAMURA ntrx300 + hALTER rOBOT LOADING CELL X2

The NTRX300 is a high-performance CNC turning center designed for precision machining and multitasking operations.

Material We Work With

- Aluminium

- Stainless Steel

- Titanium

- Mild / Carbon Steel

- Brass / Copper

- Nickel Super Alloys

- Many more…

If you have a specific material that you would like us to work with, please Contact Us

CNC Turning Services – The Benefits

Short and long batch runs – we offer turning services with the capability for both short and long batch runs, making it an efficient and accurate option for a wide range of requirements.

Variety of sectors – our turning services have been designed to suit a variety of applications across multiple sectors, for both exotic and less exotic materials, alongside complexity and component ‘footprint’.

Meet stringent parameters – sometimes the requirements on a project are very strict and exacting. Our wide range of turning services ensures that whatever the requirements, we can manufacture parts that are highly precise and remain a high standard throughout the production run.

Bespoke solutions – utilising the latest automation solutions within our Turning services makes it easier to offer a competitive, tailored solution to our customers. We have invested in our Turning and Mill/Turn technology to create this environment of high standards.

Lower your costs – turning centres with such a wide range of application flexibility means that you can lower the cost per part for simple geometries, with cost-effective solutions for more complex cases.

Customer Focused

We make sure our customers are incredibly satisfied with every order, we hold a large repeat customer base and some of our clients have been with us since the beginning.

Expert Team

Your project will be handled by professionals who care. We make sure you have a dedicated team working for you.

Quality Assurance

Get the support you need to ensure that things runs smoothly. We’re here seven days a week to answer any question.

24hr Automated Facility

We have an automated 24 hour facility and professional team to support you at all times from Mon-Fri: 7:30am - 5pm

Our Services

Our use of sliding head lathes ensures that cycle times and costs are significantly reduced. Achieving up to 39 machining positions with 8 axes, often a component can be completed in one single set-up, improving efficiencies.

Our team continues to refresh our fleet of machines, investing significantly in our Turning and Mill/Turn technology. This allows us to remain ahead of the game, providing a tailored service and solution to our customers that is hard to match within the industry.

We continue to innovate, refining our 5 axis CNC machining services for maximum output at reduced time and cost. The 5 axis provides you with the power and precision for myriad uses, maintaining accuracy and delivering consistently.

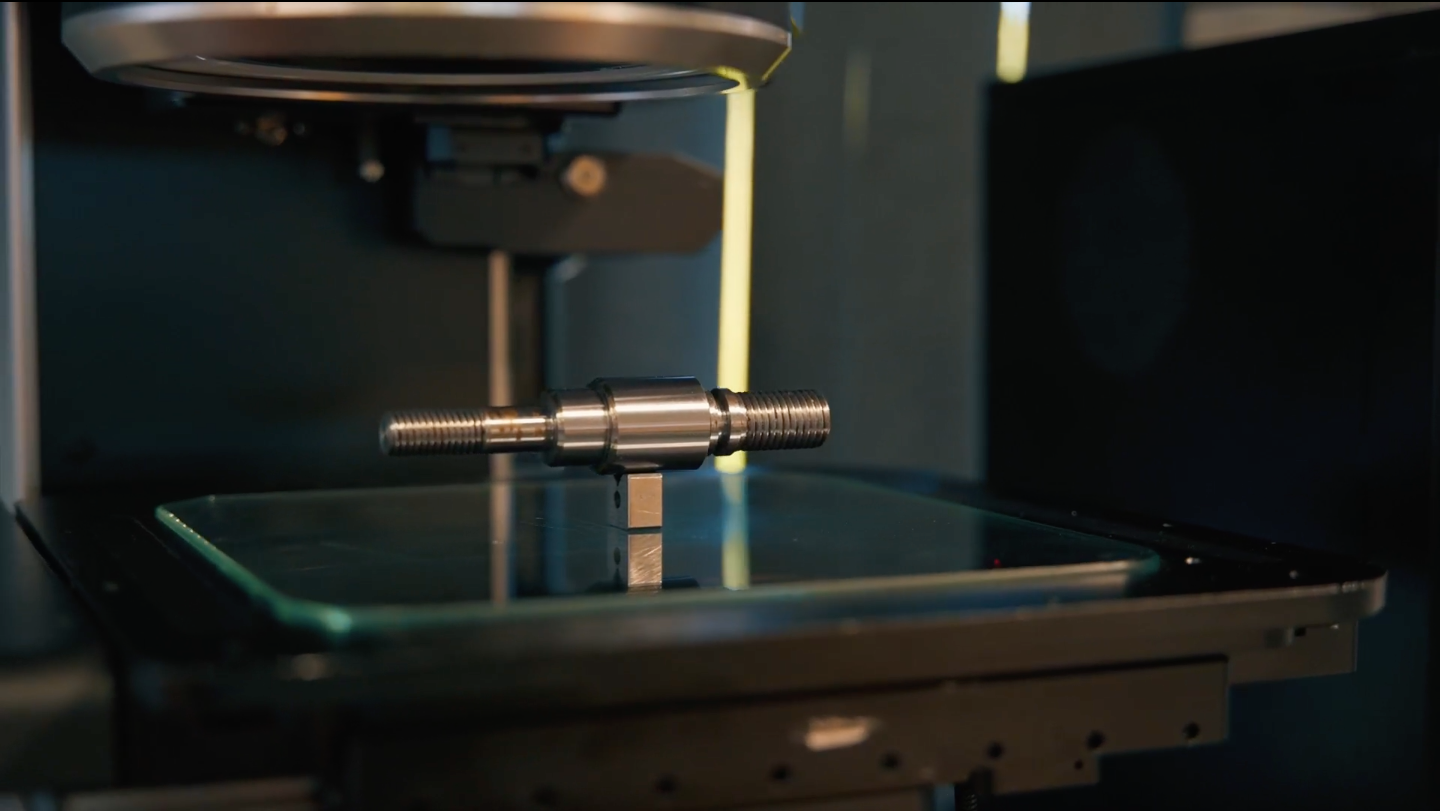

CMM inspection is another service Rotec offers to boost the accuracy and consistency of manufacturing processes. It involved precision CMM inspection services that takes CAD models and 2D drawing formats and provides a detailed report tailored to each client and process.

Our CNC Turning Company

Our specialist CNC Turning Service has been designed to push the boundaries and to continuously take advantage of the investment we put into the technology on a regular basis. What this means is that we can provide a service that assists for a wide range of applications and industries, reducing costs, raising standards, and providing flexibility and a larger capacity through automation. This allows for a completely tailored solution for customers looking for a CNC Turning service.

Contact Us

If you're a potential client and have a project we can discuss, our journey together begins here. Fill out the form and we'll be in touch or use the contact details below