~ What is CNC Prototyping? Everything you need to know ~

Introduction to CNC Prototyping

CNC machining services remain a popular and important tool when it comes to prototyping. In many cases, a CNC machining company is the best choice you can make when looking to create a 3D model prototype of a product or component, and speaking to specialists in the field will help you to understand what is required from you, and why a CNC machine is the best choice for your prototype

What is a prototype?

A prototype is an early model, or sample, of a product or component. There are a few reasons why the production of a prototype is desired in the early stage of product development. It is often to test the design and the concept of the product or component, to see where the design can be changed to improve the final product. It is sometimes used as a way of testing out the process of manufacturing, including processes, techniques, machinery, and materials used.

What is CNC prototype machining?

An innovative technique that brings the precision and accuracy of rapid CNC machining services into the world of prototype manufacturing. This involves the use of a machine that is controlled by a computer, carving out the prototype model or component from a solid block of raw material, usually plastic or metal. This process is used to identify any potential flaws in the design or in the manufacturing process before committing to a long production cycle. It is a cost-effective solution for one-off prototype models or small-batch productions.

CNC prototype machining brings together CNC machining and rapid prototyping, creating a physical prototype or model using a CAD or 3D model and computer numerical control (CNC) machines. This results in a highly precise and accurate prototype part or component that matches specific and tight specification requests.

What are the different methods of CNC prototyping?

There are a few different methods that CNC machining can be used for when it comes to producing a prototype part. A subtractive manufacturing process, the following are CNC operations used to create prototypes:

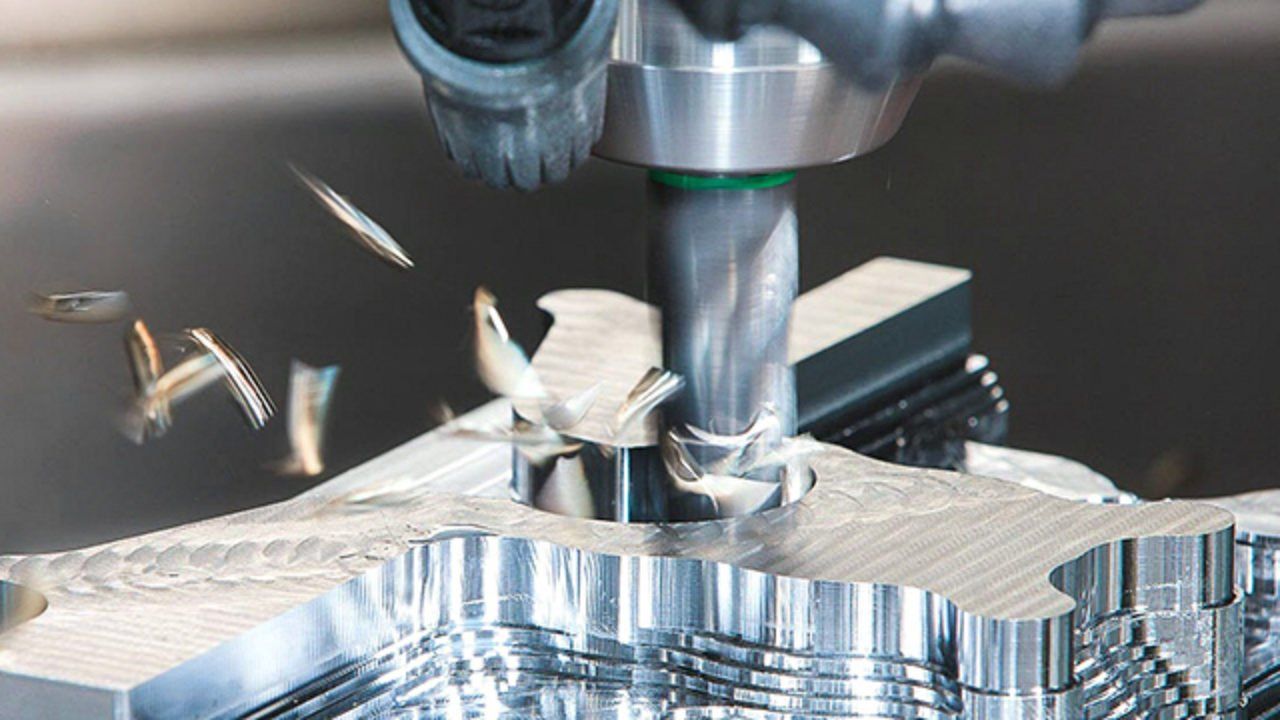

Milling

This is a method where the cutting tool rotates and is a versatile method of fabrication that offers high precision and tolerance.

CNC Milling can be performed using a wide variety of materials and is also fast paced, even when producing the most intricate of components.

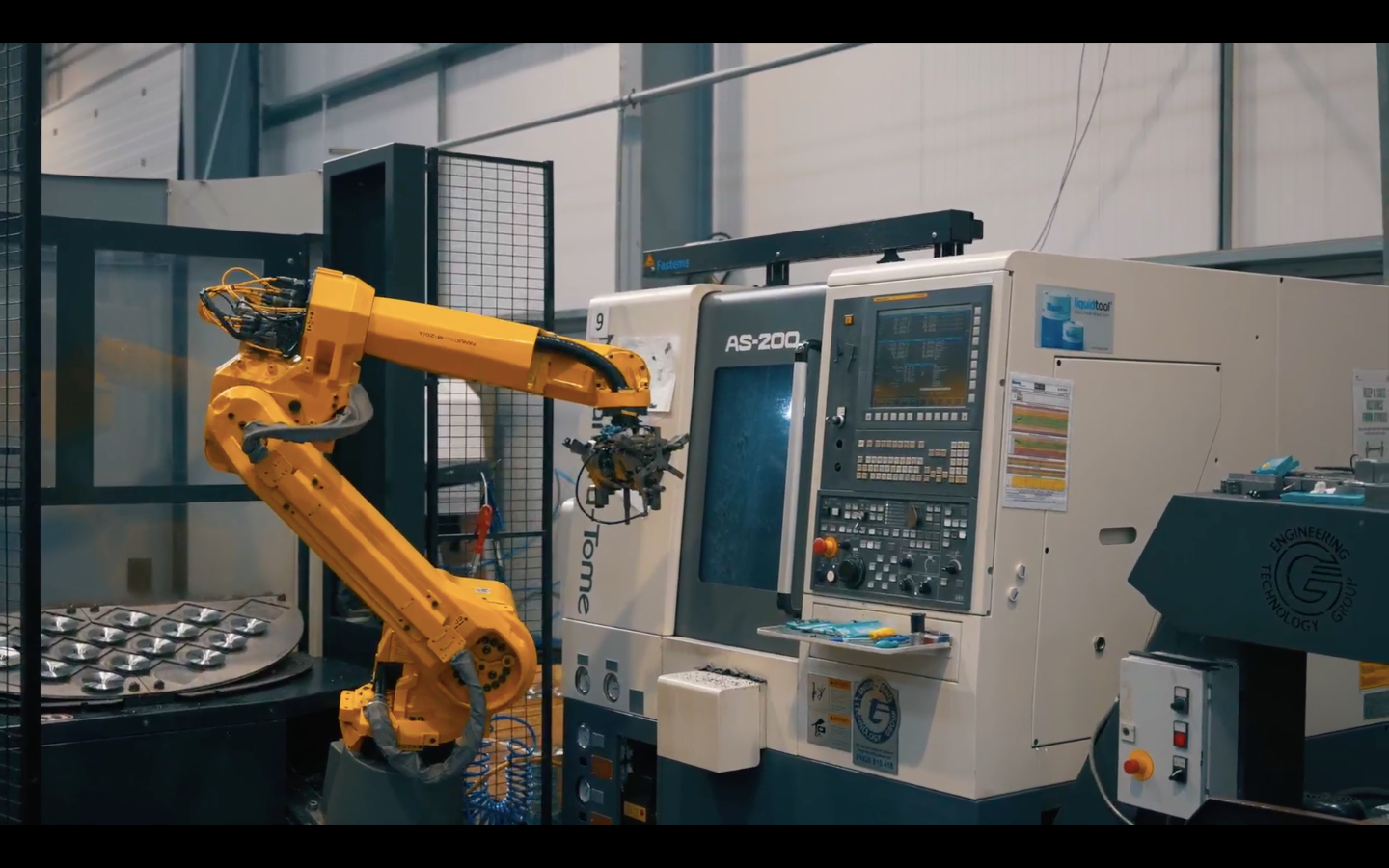

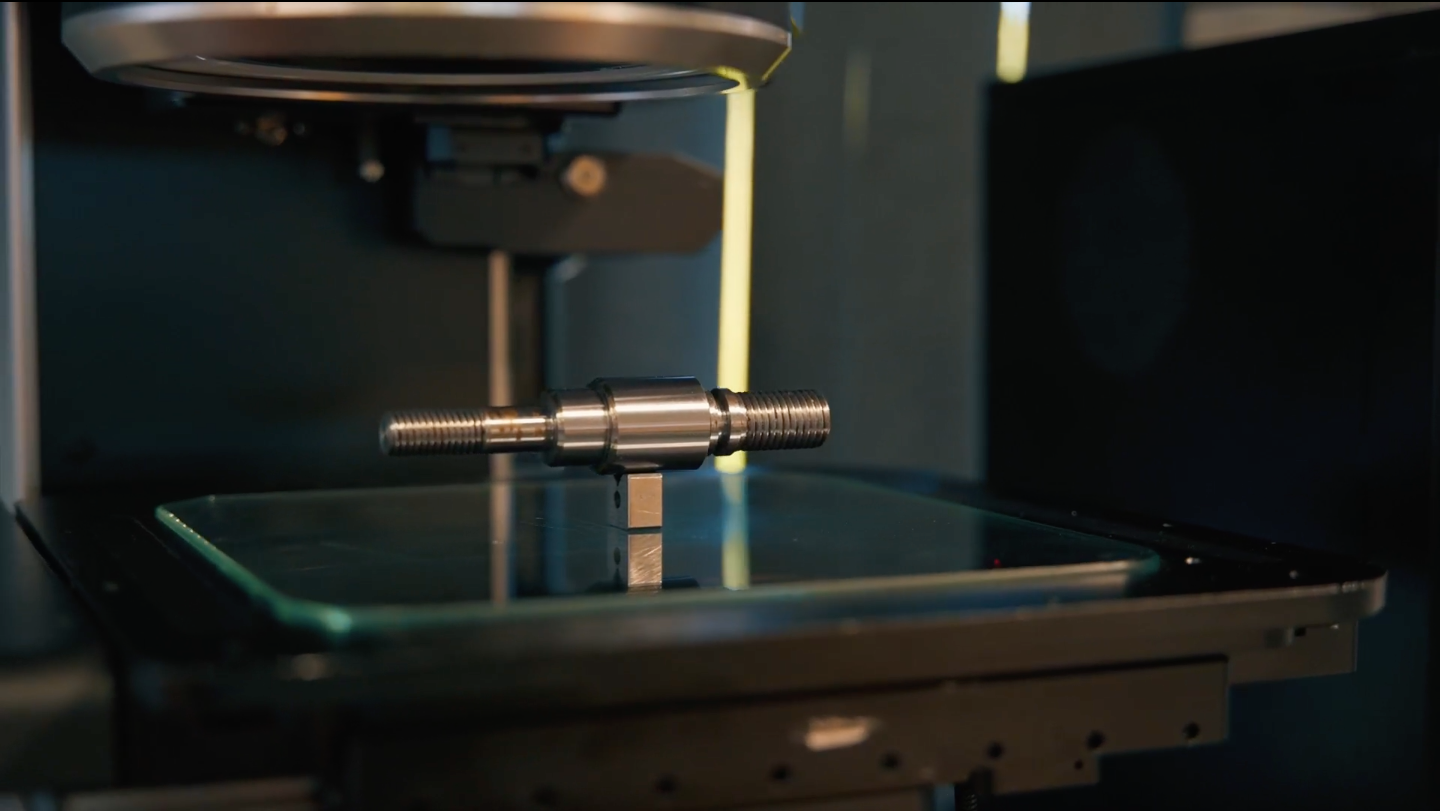

Turning

CNC Turning is a process that is the opposite to what we have described with milling above. The material being worked on rotates rather than the tool used to cut the material. The tool is instead connected to the rotating material to remove metal chips or swarf, providing a great level of accuracy in the process.

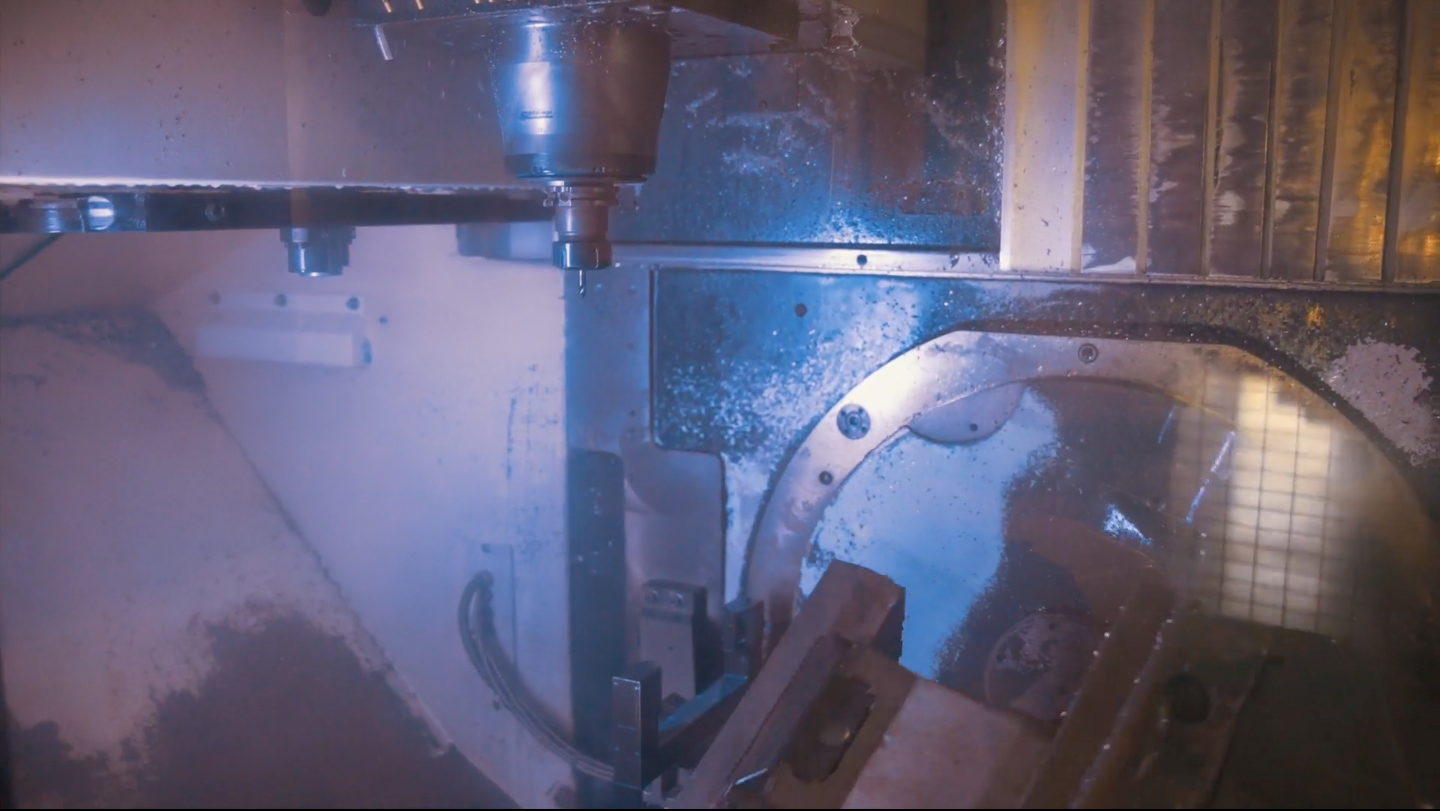

Grinding

This is the process where material is removed by the spinning of a grinding wheel. This adds to the levels of high precision that is required when working on a metal part or component. This process also results in a high level of surface quality.

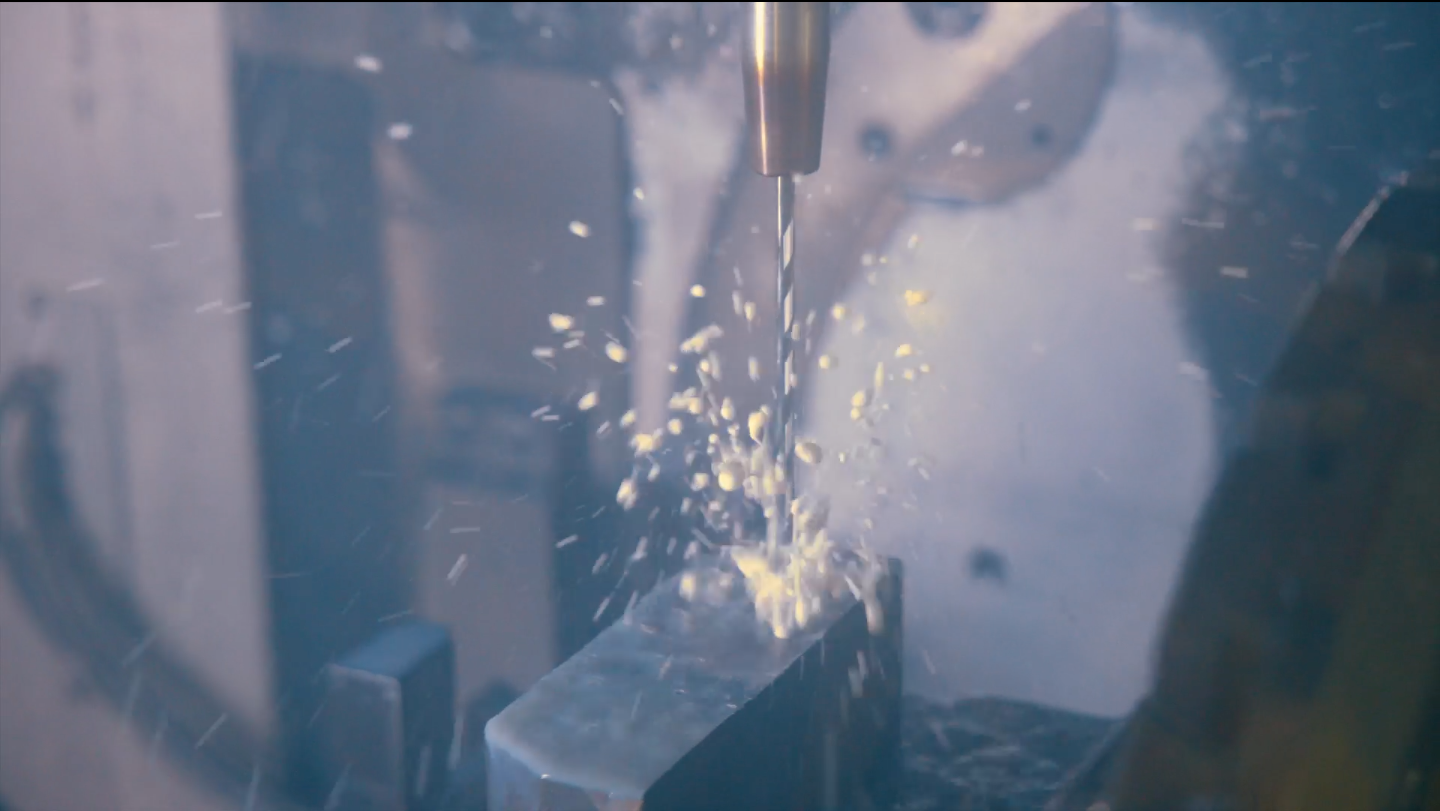

Drilling

CNC drilling machines are used to automate the task of drilling holes into the material with precision, making for an economical solution to the overall project.

Sectors CNC machined prototypes are used in

There are a wide range of sectors and applications that are used for to create prototype components, parts, and models, including:

- Medical sector – equipment that requires microscopic precision and robust materials, high tolerance demands, and quality.

- Aerospace industry – precision quality standard for the smallest of aircraft parts where a slight error could be catastrophic.

- Automotive industry – perfect to check parts and components before mass production.

- Military and defence – intricate nature of vehicles, equipment, and ammunition requires accuracy of design and production.

- Architecture and construction – fabrication of interior and exterior models during planning stage of projects.

- Oil and energy sector – for exploration of future green energy resources, and robust parts for resource extraction.

What are the benefits of CNC machining services for prototypes?

For rapid and accurate prototyping needs, CNC machining services offer the best choice moving forward. The benefits include:

- Fast and efficient process – CNC prototyping is a fast and efficient process that requires little human supervision, bringing 3D models to life with reduced lead times.

- Accuracy and precision – the accuracy levels are much higher with CNC prototyping than other methods, making it ideal for products with tight tolerances.

- Simple modification – corrections for designs are often needed, and with CNC machines this is a simple process, reducing time on making changes to a product prior to market.

- No fixed tooling required – most other processes for prototyping require specialist tools, such as the hardened dies required for injection molding.

- Consistency – consistency is everything when planning for a large production run and long cycle. CNC machine services provide reliability and a high level of consistency and repeatability.

Speak to a precision engineering company with the experience, machinery, and technical expertise that helps you to put together a prototype that fits the bill. There could be a number of reasons why you wish to put together a prototype, but it is important that you have accuracy and precision when the time comes, CNC machinery helps to achieve this and gives you the best platform for future success.

Rotec Aerospace Limited, Enterprise Way, Vale Business Park, Evesham WR11 1GS United Kingdom

Phone: 01386 424111

Email: Info@rotec-ltd.com

Office Hours :

Mon-Fri : 7:30am - 5pm