~ What is 5-axis CNC Machining? ~

Understanding 5 axis CNC machining

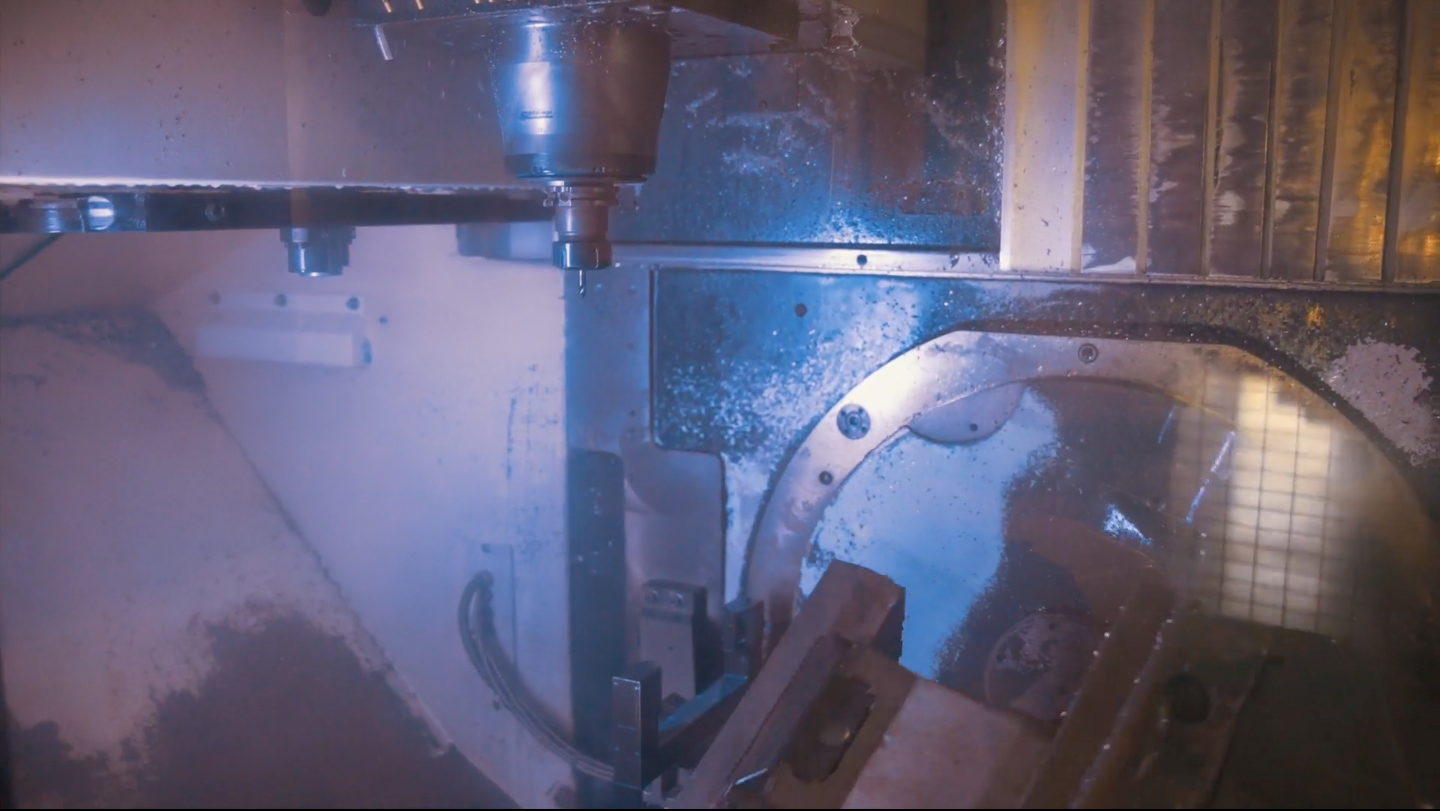

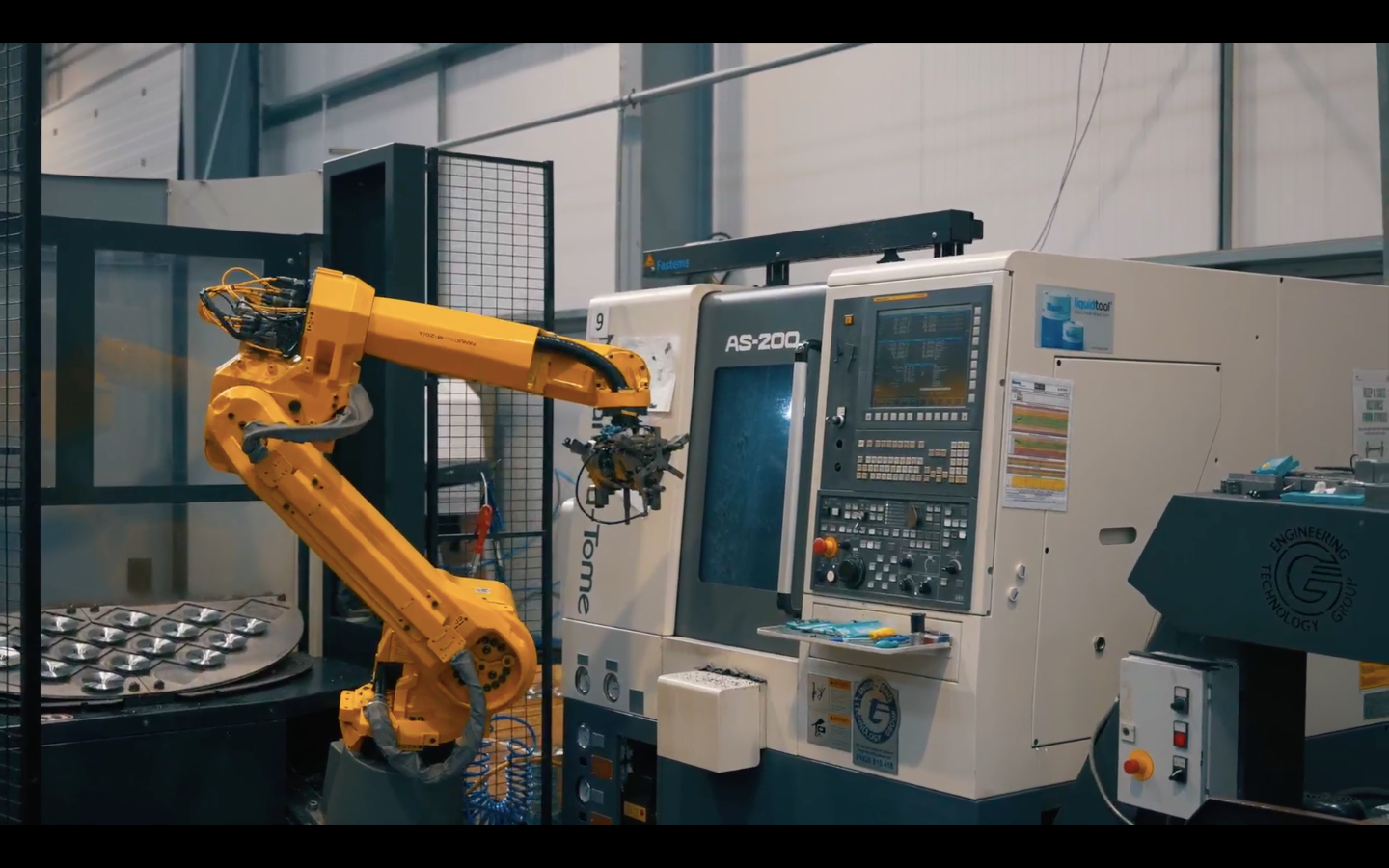

5-axis CNC machining is a versatile process that implements subtractive machining technologies. With this process, a piece of material is cut into a shape, with the cutting tools working on 5 axes to help improve the efficiency, accuracy, and speed of the finished component or part.

The process of CNC machining utilises the CAD (Computer-Aided Design) file to program the cutting tools, and the process is managed by a CNC (Computer Numerical Control). Once the parts have been programmed, the process is fully automated, cutting down the input of manual processes, which can significantly improve efficiency and levels of safety. Due to the increased number of axes, there are greater potential capabilities when compared with three-axis CNC machines and two-axis machines.

How does 5 axis CNC machining work

In much the same way as other CNC machines work, the 5-axis CNC machine works based on the instructions from a computer. The instructions for the tool parts are programmed, and the 5-axis process begins with the creation of the 3D-CAD model of the end result. This is then exported into the CAM software and is converted into the G-code for the CNC machine to work from. The instruction controls the movement of the cutting tools along clear paths and along linear axes (X, Y, and Z), whilst also controlling the rotational axes (A and B) for the direction of the worktable. This helps to provide an accurate and precise engineering solution.

How much does 5 axis CNC machining cost?

The cost will always depend on the specifics of the project at hand. Although the cost of using a 5-axis CNC machine is higher than a 3 or 2-axis machine, the end result is of a more accurate and polished manner. There are more significant set-up processes to achieve with a 5-axis machine, but once it is set-up the process is faster and more accurate, and therefore more cost-effective for larger volumes of orders and longer production runs.

Why is there less fixturing with 5 axis machining

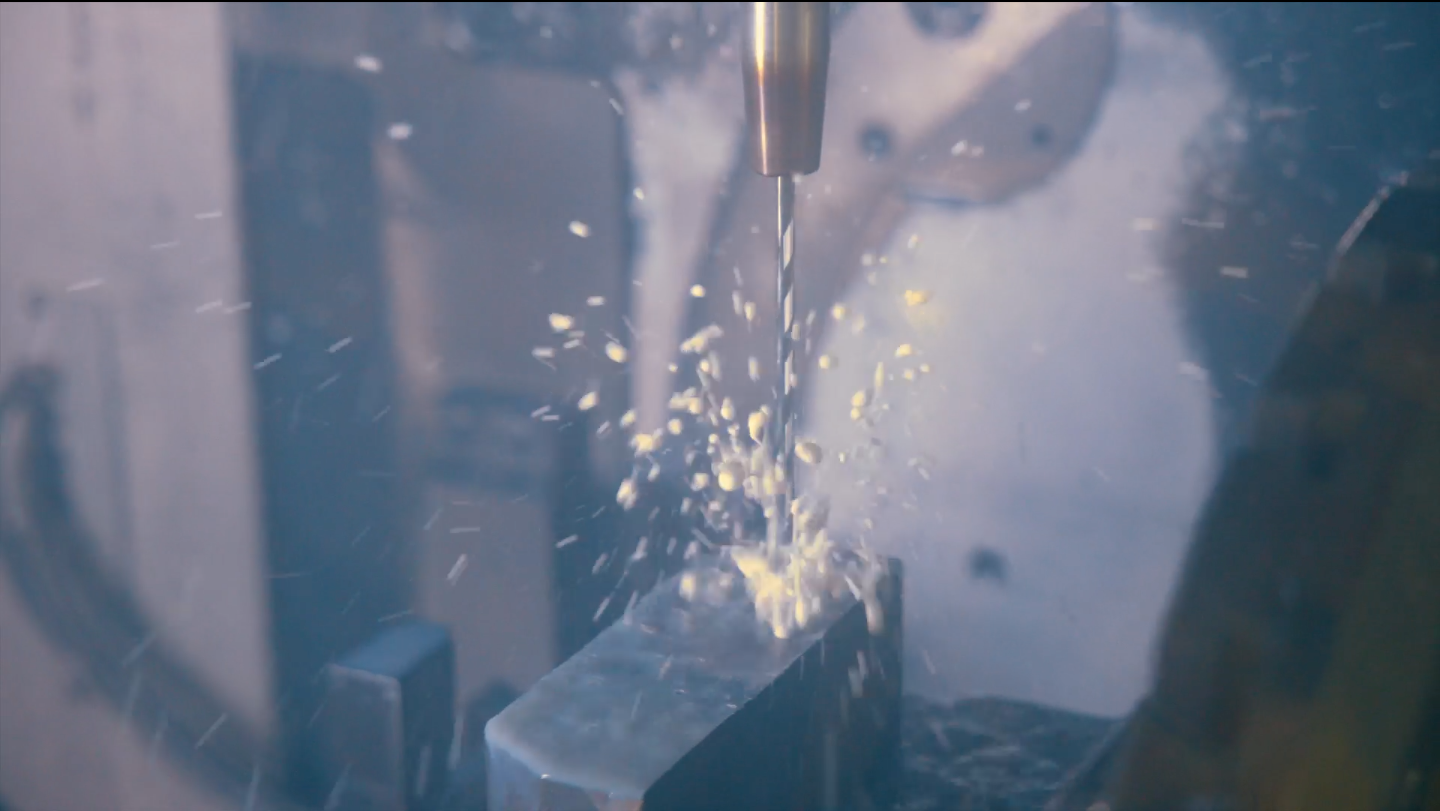

These types of machines can reach five sides of the part, which helps with a complex geometrical component. It has the ability to reach the most complex of angles and to cut areas that a 3 or 2-axis machine could not reach. The range of motion is much wider, meaning there is less fixturing than with other types of CNC milling.

Benefits of 5 axis machining

There are a few good reasons why five axis CNC machining is a popular choice. Here, we take a look at some of the benefits of 5 axis machining.

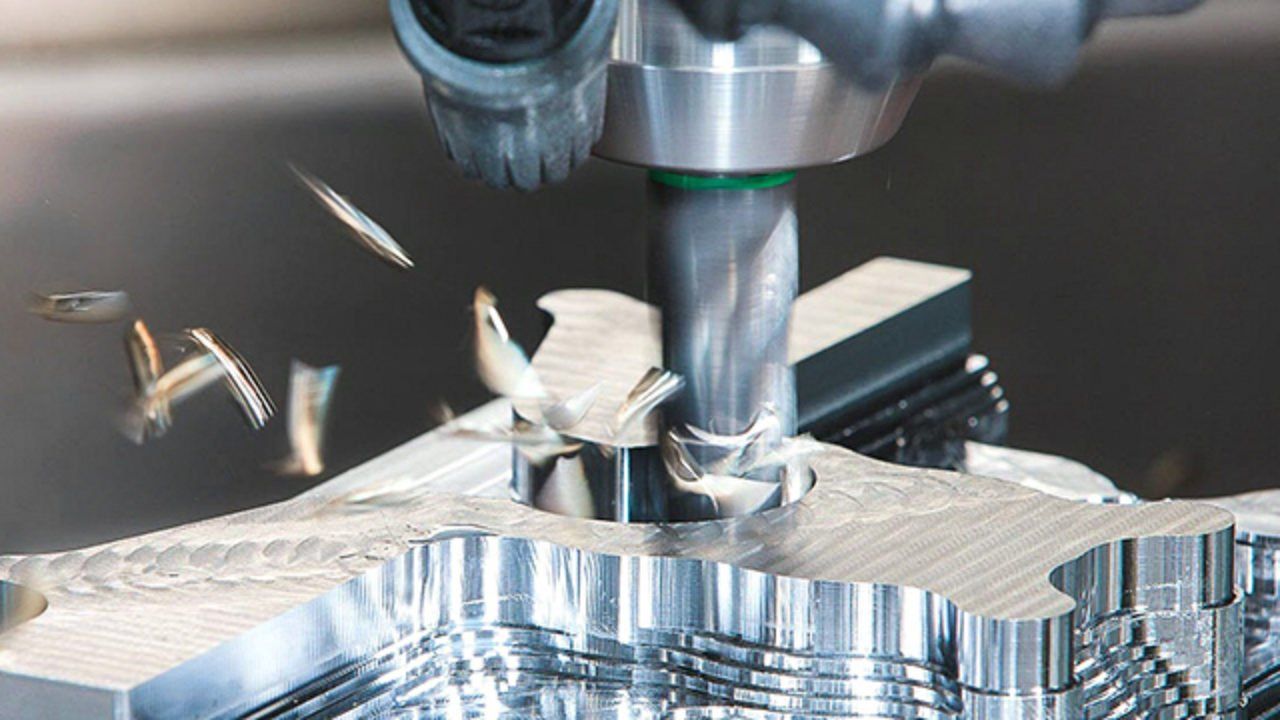

High-quality finish

5 axis CNC machining has such high capabilities as a cutting tool that it provides a higher quality finish, as the cutting tools can be shorter on this type of machine. The configuration allows for a reduction in vibration, which reduces the chance of ‘chatter’ marks, and the end result is smoother as a consequence. This cuts down the time and cost associated with often, much-needed hand finishing.

Fast output

The 5-axis machining works at a high speed and also utilises automation that means that there is a minimisation of manual intervention within the process. The multiple axes make it work as a whole workpiece that can cut everything in one go, instead of the need to stop and restart as you work through different aspects of the finished piece.

Applications of CNC Machining.

Increased complexities

Where there would have been a need for multiple set-ups in the past to produce complex shapes and geometries, a five axis CNC machine allows for potentially complex shapes in the end result, and with only one set-up and fixture in most cases. This significantly increases levels of efficiency and productivity.

Cons of 5 axis machining

Along with the great qualities that 5-axis CNC machines bring to the table, they are not the right choice for every client and project. This could be for any of the following reasons:

A higher expense

Due to the nature of efficiency and potential for complex geometries, the cost associated with a 5-axis machine is naturally higher than the cost of a 3-axis machine. Utilising our specialist services will be cost-effective for those who require the use of a 5-axis CNC machine over time though.

Trained operators

If you do not have a highly trained operator in-house, it makes sense to outsource your CNC machining needs to a company such as ours with the experience and trained operators to effectively deal with your request. Operating a 5-axis CNC machine is not something that just anybody can do, there is specific training that must be followed in order to run them safely and efficiently.

Less hands-on labour

The fact that 5 axis CNC machining is so efficient and can perform tasks at a much faster speed and without the need for multiple set-ups, there is a danger that job roles can be lost. However, it also ensures that a greater number of orders can be fulfilled, and with the growth in business, companies can expand and take on more staff in different areas, especially if this specialist requirement is outsourced. More focus can be given to other areas of a business instead.

Types of 5 axis machining

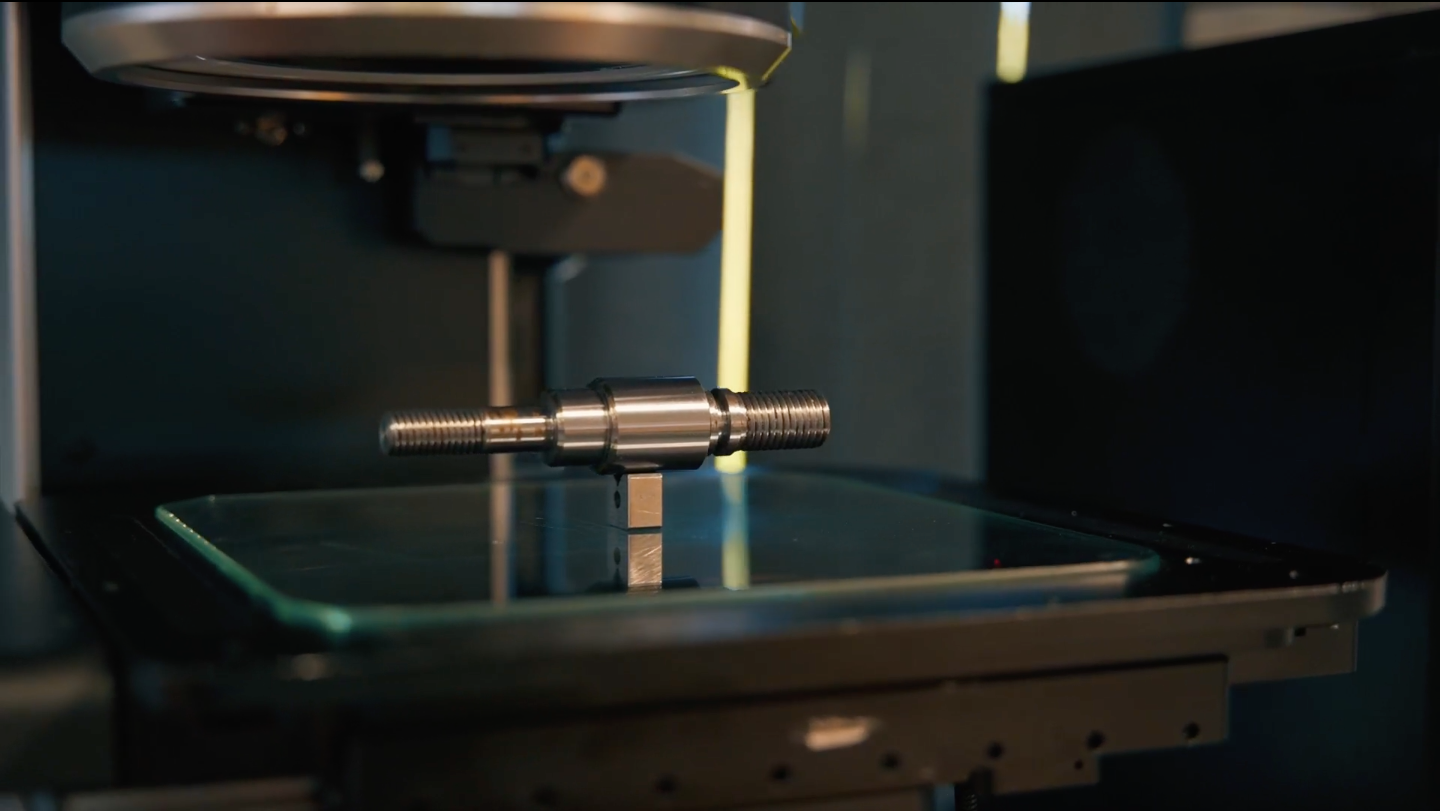

At Rotec we have the following types of 5-axis machining as part of our state of the art setup:

- DMG Mori DMU 50U

- DMU 50 3rd Generation + PH150 Pallet Loaderstar

- Star SR-32JIII Type B

- Citizen C16

- STAR SA-12

- Nakamura NTY-3

With such a wide range of machines and configurations within 5-axis CNC machining, it is no wonder that it is used within such detailed and important sectors such as the automotive industry, aerospace, defence and power industries. It can also be used within the medical sector to help with the advancement of the manufacturing of surgical instruments amongst other things.

If you have any questions about our 5 Axis machining capabilities please

contact our team today.