~ Choosing the Right Configuration: 3-Axis vs. 4-Axis vs. 5-Axis CNC Machining ~

Understanding the differences between various CNC machining configurations is crucial for optimal manufacturing.

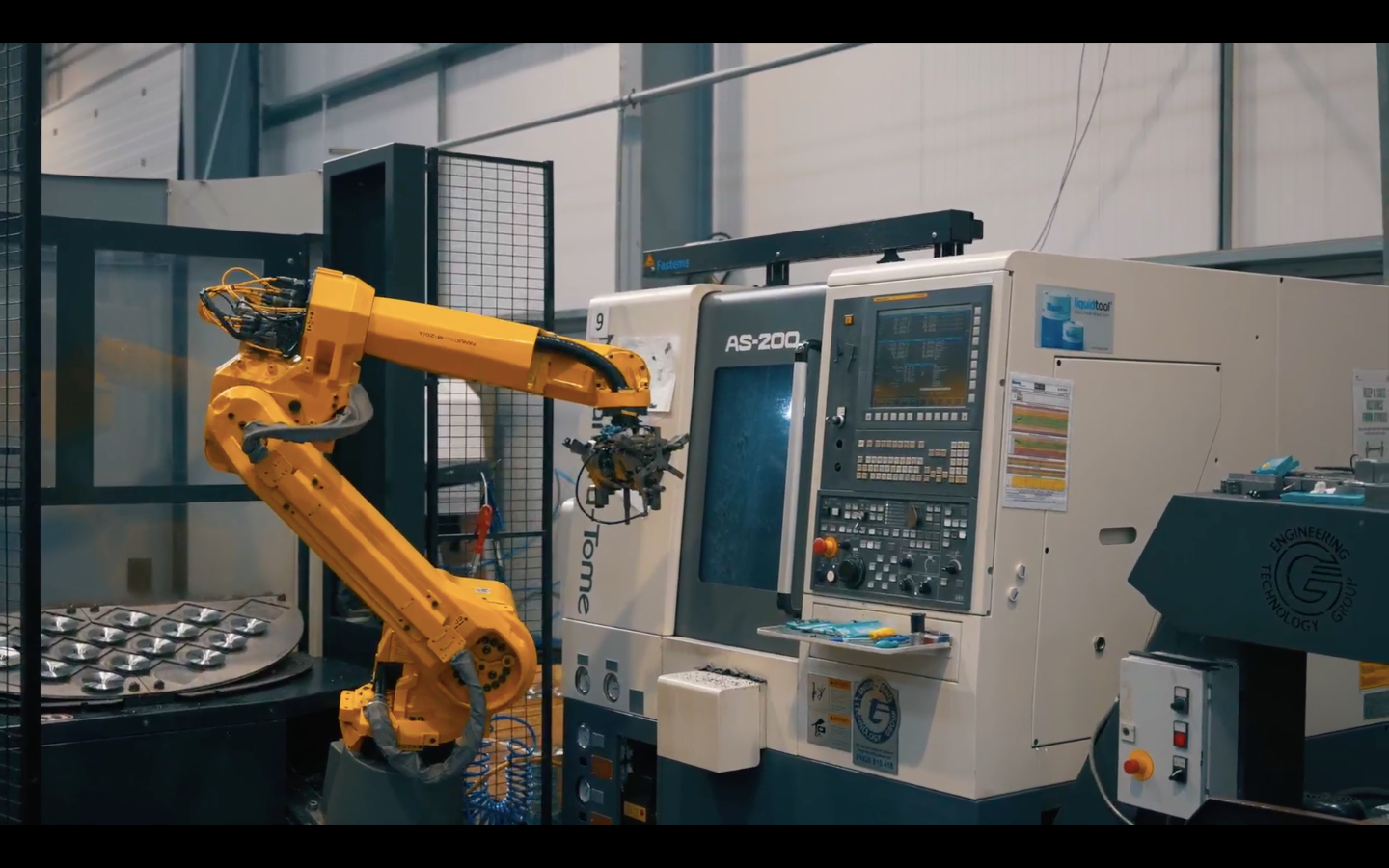

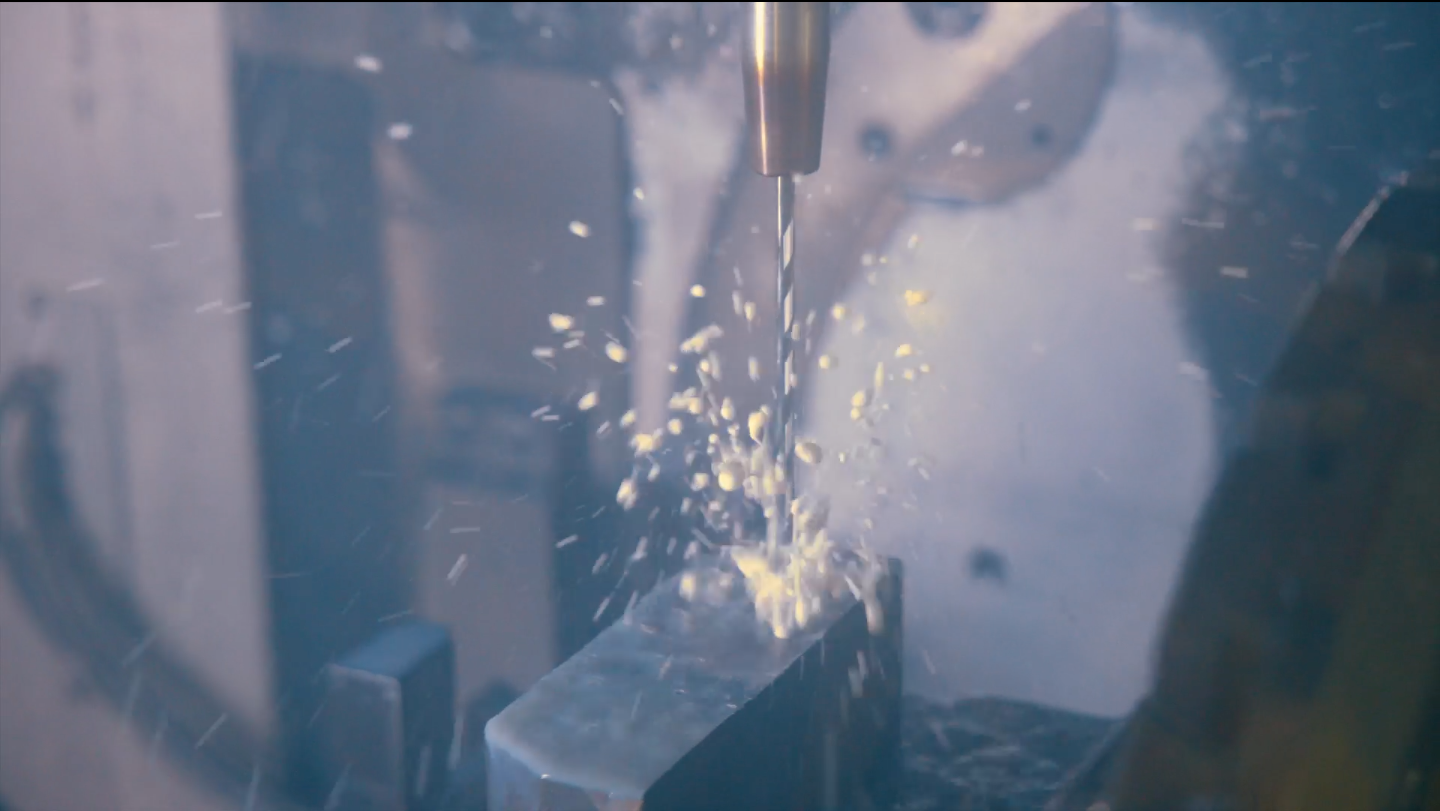

In the manufacturing world, CNC machining has revolutionized the way parts and components are produced. CNC (Computer Numerical Control) machines offer unparalleled precision and efficiency, making them indispensable in various industries. When it comes to CNC machining, there are different configurations available, such as 3-axis, 4-axis, and 5-axis CNC machining systems. Each option brings its own set of advantages and considerations.

In this article, we aim to provide a comprehensive comparison of these three configurations, highlighting their main differences and offering guidance on selecting the most suitable option for specific use cases. But before we dive in, let's first understand a little bit about each one of them and their features, one by one.

What is 3-axis CNC Machining?

3-axis CNC machining refers to a computer-controlled machining process that operates along three linear axes: X, Y, and Z. The term "3-axis" represents the number of directions in which the cutting tool can move to perform machining operations, namely horizontal, vertical and depth-wise.

The combination of these three axes provides a three-dimensional range of motion, enabling the CNC machine to perform a variety of cutting operations and create complex shapes with precision. 3-axis CNC machines are commonly used for manufacturing parts with relatively flat or prismatic surfaces, as they lack the additional rotational capabilities found in higher-axis systems. They are widely employed in various industries, including automotive, aerospace, electronics, and more, for producing components like brackets, panels, housings, and other parts that do not require intricate curves or undercuts.

Some key features of 3-axis

CNC machining include:

a. Simplicity and Cost-Effectiveness: 3-axis machines are typically less complex and more affordable compared to their multi-axis counterparts, making them ideal for small to medium-sized businesses or startups with budget constraints.

b. Limited Capability for Complex Geometry: Due to the lack of rotational axes, 3-axis machines have limitations in machining complex geometries, such as undercuts, tapered surfaces, and curved profiles. They are best suited for flat or prismatic parts.

c. Versatility: 3-axis machines can handle a wide range of materials, including plastics, metals, and composites. They are commonly used in automotive, aerospace, and consumer electronics industries for producing components like brackets, housings, and panels.

Despite their limitations, 3-axis machines are highly versatile and can accomplish a wide range of manufacturing tasks. The simplicity of their design makes them easy to operate and maintain, and they are an excellent starting point for companies entering the CNC machining field.

What is 4-axis CNC Machining?

4-axis CNC machining refers to a computer-controlled machining process that adds an additional rotational axis, typically referred to as the A-axis, to the traditional X, Y, and Z linear axes. This configuration allows the cutting tool to rotate around the workpiece, providing increased flexibility in machining operations.

The addition of the A-axis provides the ability to rotate the workpiece, allowing for machining operations from different angles and orientations without the need for repositioning. This feature is particularly useful for producing parts with rotational symmetry, such as gears, impellers, and sculptures. 4-axis CNC machines are capable of creating undercuts, curved surfaces, and cylindrical features, expanding the range of complex geometries that can be machined.

By reducing the need for multiple setups and repositioning, 4-axis CNC machining enhances efficiency and reduces production time. It strikes a balance between complexity and cost, making it a popular choice for automotive, aerospace, medical devices, and other industries, where parts require machining from different angles to achieve the desired specifications.

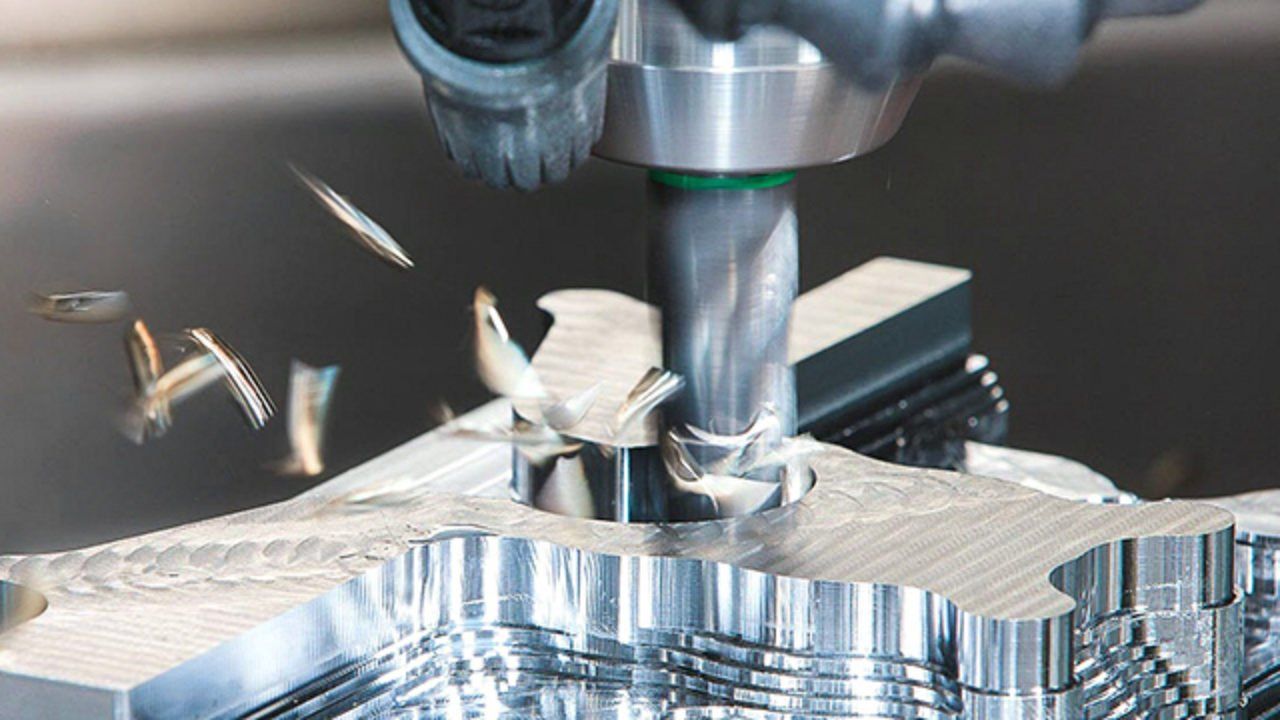

What is 5-axis CNC Machining?

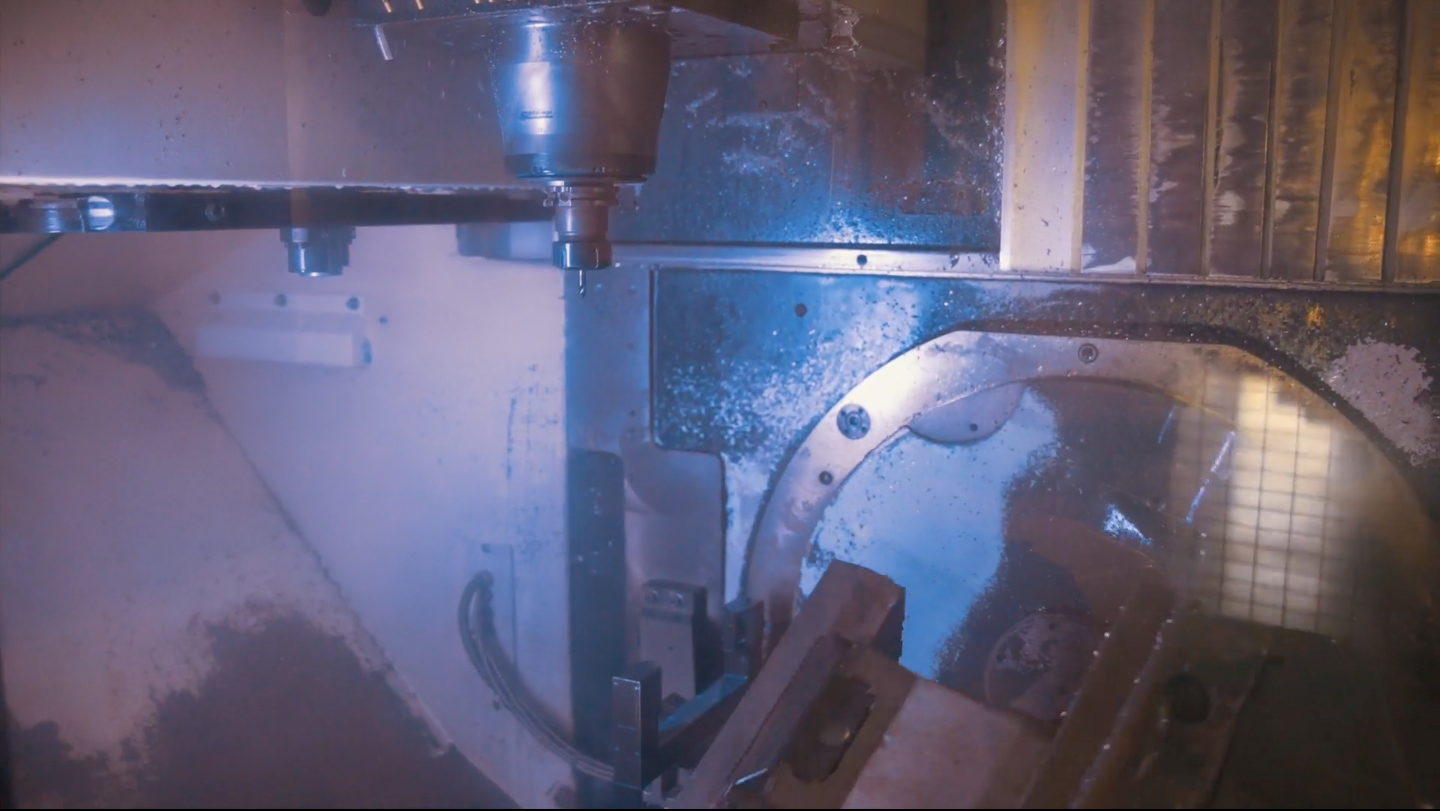

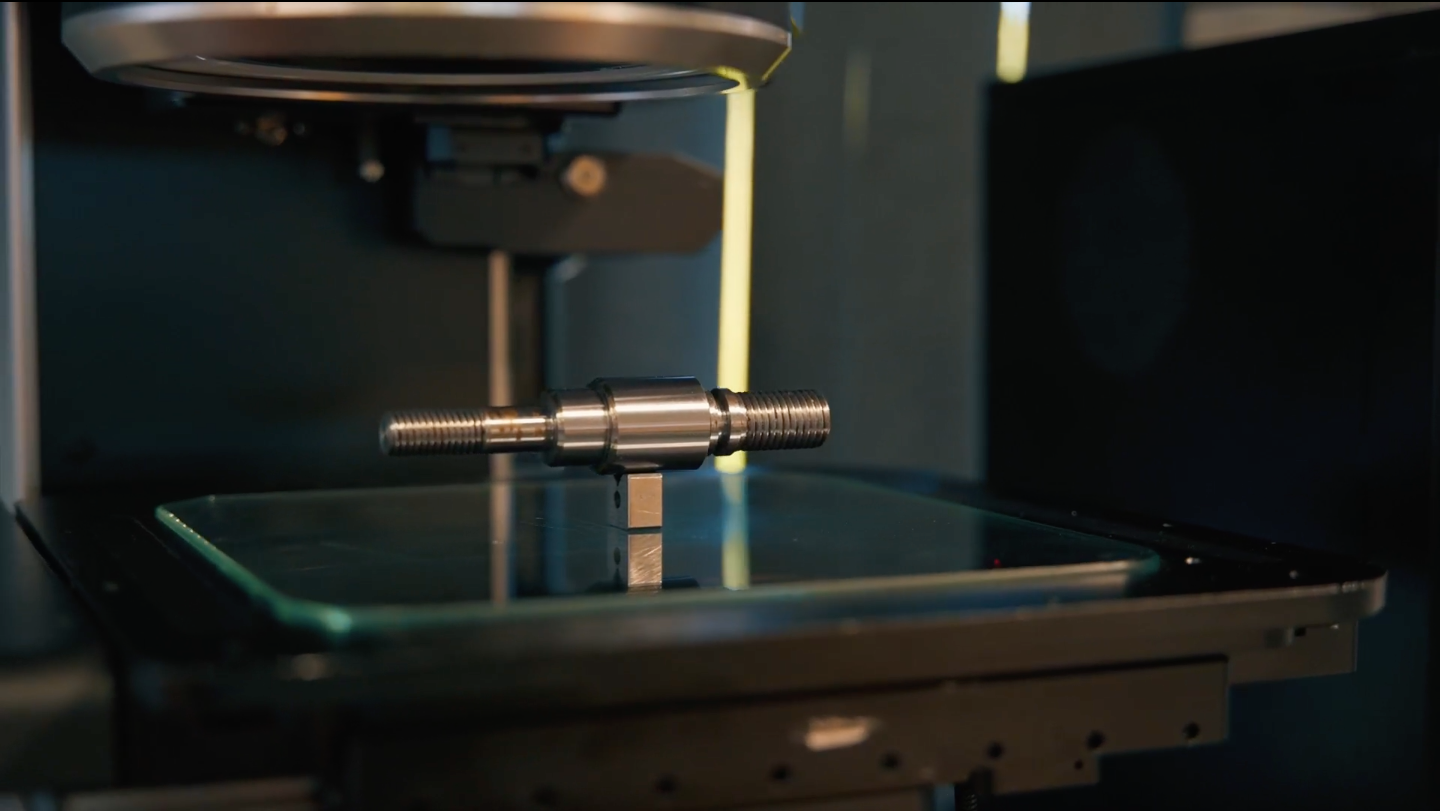

5-axis CNC machining refers to a computer-controlled machining process that incorporates five axes of movement to achieve enhanced versatility and precision in machining operations. In addition to the X, Y, and Z linear axes, a 5-axis CNC machine includes two rotational axes, typically referred to as the A-axis and B-axis.

The inclusion of the A-axis and B-axis in 5-axis CNC machining enables the cutting tool to approach the workpiece from multiple angles and orientations. This capability allows for the machining of highly complex geometries, such as undercuts, deep pockets, sculpted surfaces, and intricate curves. The ability to tilt and rotate the cutting tool reduces the need for multiple setups and repositioning, thereby enhancing efficiency and precision.

5-axis CNC machines are commonly used in industries such as aerospace, automotive, medical, and mould-making. They are capable of producing parts with tight tolerances and intricate features, including turbine blades, aerospace components, complex moulds, and artistic sculptures. The versatility and precision offered by 5-axis CNC machining make it a preferred choice for applications that demand the highest level of complexity and accuracy.

Comparison of 3-Axis, 4-Axis, and 5-Axis CNC Machining

To determine which CNC machining option is best for a specific use case, it's important to consider factors such as the complexity of the part, precision requirements, production volume, and budget. Here's a detailed breakdown of which option is most suitable for different use cases:

3-Axis CNC Machining

Use Case:

3-axis CNC machining is best suited for producing simple parts with relatively flat surfaces and minimal complexity. It is commonly used in automotive, aerospace, and consumer electronics industries for manufacturing components like brackets, housings, and panels.

Advantages:

- Simplicity and Cost-Effectiveness: 3-axis machines are less complex and more affordable compared to higher-axis systems, making them ideal for small to medium-sized businesses or those with budget constraints.

- Versatility: 3-axis machines can handle a wide range of materials, including plastics, metals, and composites.

- Wide Application Range: 3-axis CNC machining is suitable for various industries and can produce a diverse range of parts with flat or prismatic surfaces.

Limitations:

Limited Capability for Complex Geometries: Due to the absence of rotational axes, 3-axis machines have limitations in machining complex geometries, such as undercuts, tapered surfaces, and curved profiles.

4-Axis CNC Machining

Use Case: 4-axis CNC machining is ideal for parts with rotational symmetry or features requiring machining from different angles. It finds applications in industries such as automotive, aerospace, and medical devices.

Advantages:

- Enhanced Flexibility: The addition of the rotational A-axis provides increased flexibility in machining complex parts with undercuts, curved surfaces, and cylindrical features.

- Reduced Setups: 4-axis machines can rotate the workpiece, eliminating the need for frequent repositioning and reducing setup time.

- Versatility: 4-axis machines can still handle a wide range of materials and are suitable for various industries.

Limitations:

Restricted to One Additional Rotational Axis: While 4-axis machining provides additional flexibility compared to 3-axis, it is still limited to a single rotational axis, which may not be sufficient for certain complex parts.

5-Axis CNC Machining

Use Case: 5-axis CNC machining is recommended for highly complex parts with intricate geometries, tight tolerances, and the need for multi-angle machining. It finds applications in the aerospace, automotive, medical, and mould-making industries.

Advantages:

- Unparalleled Precision: The ability to tilt and rotate the cutting tool from multiple directions allows for precise machining of intricate features, eliminating the need for multiple setups and reducing errors.

- Complex Geometry Capability: 5-axis machines excel in machining complex geometries, including undercuts, deep pockets, and sculpted surfaces, enabling the creation of highly intricate parts.

- Time and Cost Efficiency: By reducing the number of setups required, 5-axis machining enhances productivity, minimizes production time, and can lead to cost savings in specific scenarios.

Limitations:

- Higher Cost: 5-axis machines are generally more expensive than 3-axis or 4-axis machines due to their advanced capabilities.

- Specialized Expertise: Operating and programming 5-axis machines may require specialized knowledge and expertise.

Choosing the Right Option: 3-axis vs 4-axis vs 5-axis Machining

While there’s no rule of thumb when it comes to choosing which CNC machining configuration is best suited for your manufacturing process, here are some general guidelines to consider:

3-Axis CNC Machining: Suitable for producing simple, flat parts with minimal complexity, making it a cost-effective option for small to medium-sized businesses.

4-Axis CNC Machining: Ideal for parts with rotational symmetry or features requiring machining from different angles. It strikes a balance between cost and complexity, making it suitable for various industries.

5-Axis CNC Machining: Recommended for highly complex parts with intricate geometries and tight tolerances. It offers superior precision and versatility, but it comes at a higher cost.

The choice between 3-axis, 4-axis, and 5-axis CNC machining depends on the specific requirements of the parts or components being manufactured. While 3-axis machines offer versatility and cost-effectiveness for simpler parts, 4-axis machines provide increased flexibility and are suitable for parts with rotational symmetry. 5-axis machines offer unparalleled precision and complex geometry capabilities but come at a higher cost. By considering the complexity of the part, precision requirements, production volume, and budget, manufacturers can determine the most suitable CNC machining option for their specific use case.

Final Thoughts

Whether you're producing simple flat parts, parts with rotational symmetry, or highly complex components, there is a CNC machining configuration that can meet your specific requirements and drive your manufacturing processes forward.

At Rotec, we have experience in identifying and implementing manufacturing solutions with a wide range of applications across various industries. To learn more about the topic or to connect with our CNC machining experts,

contact us at 01386 424111 or sales@rotec-ltd.com.

Rotec Aerospace Limited, Enterprise Way, Vale Business Park, Evesham WR11 1GS United Kingdom

Phone: 01386 424111

Email: Info@rotec-ltd.com

Office Hours :

Mon-Fri : 7:30am - 5pm