~ A Guide To Sheet Metal Fabrication ~

What is Sheet Metal Fabrication?

Sheet Metal Fabrication is the process of transforming flat sheets of steel or other metals into various structures or products. Metal fabrication plays an important role in industries like construction, aerospace, and automotive, evolving over centuries with technological advancements. This process is responsible for numerous everyday items, from precision parts in machinery to large metal structures.

Sheet metal fabrication is the process of creating metal structures by cutting, punching, bending, and assembling sheets of metal. This process involves a series of techniques to transform raw metal sheets into parts or structures used in various applications.

How Does Sheet Metal Fabrication Work?

The fabrication process begins with designing. Precise models are created using CAD software. Following design, programming translates these models for machinery. The actual fabrication involves cutting (often by laser), punching for details, bending, and forming the metal into desired shapes. Welding techniques are then used for assembling the parts. The final steps include finishing touches like sandblasting, priming, painting, and powder coating to enhance durability and aesthetics.

The Fabrication Process

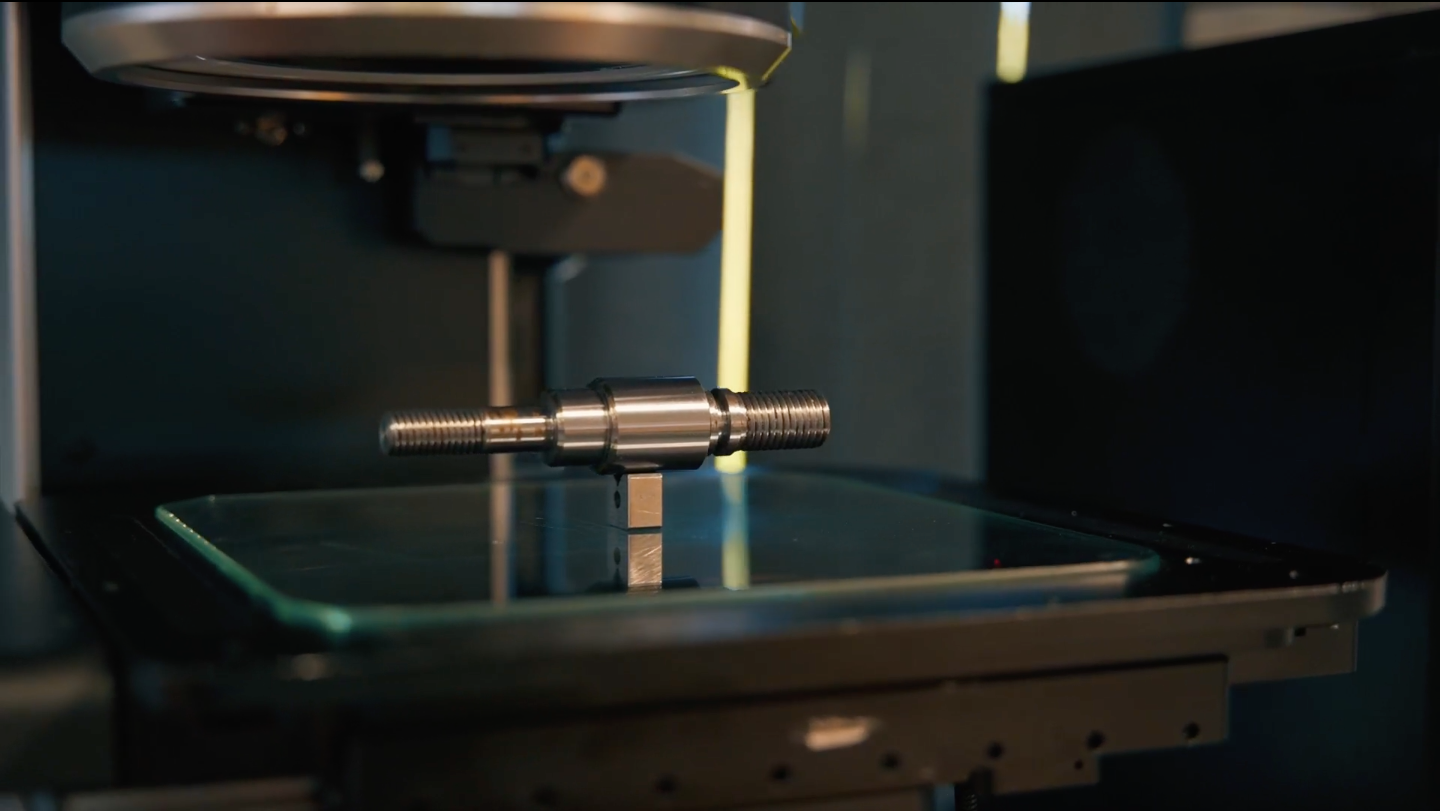

Designing

This phase involves creating initial sketches or models using CAD software. Factors like product use, dimensions, materials, and finishes are meticulously planned to ensure efficiency and quality.

Programming

Post-design, these designs are then converted into machine-readable formats. This step optimizes material utilization and prepares for the cutting phase.

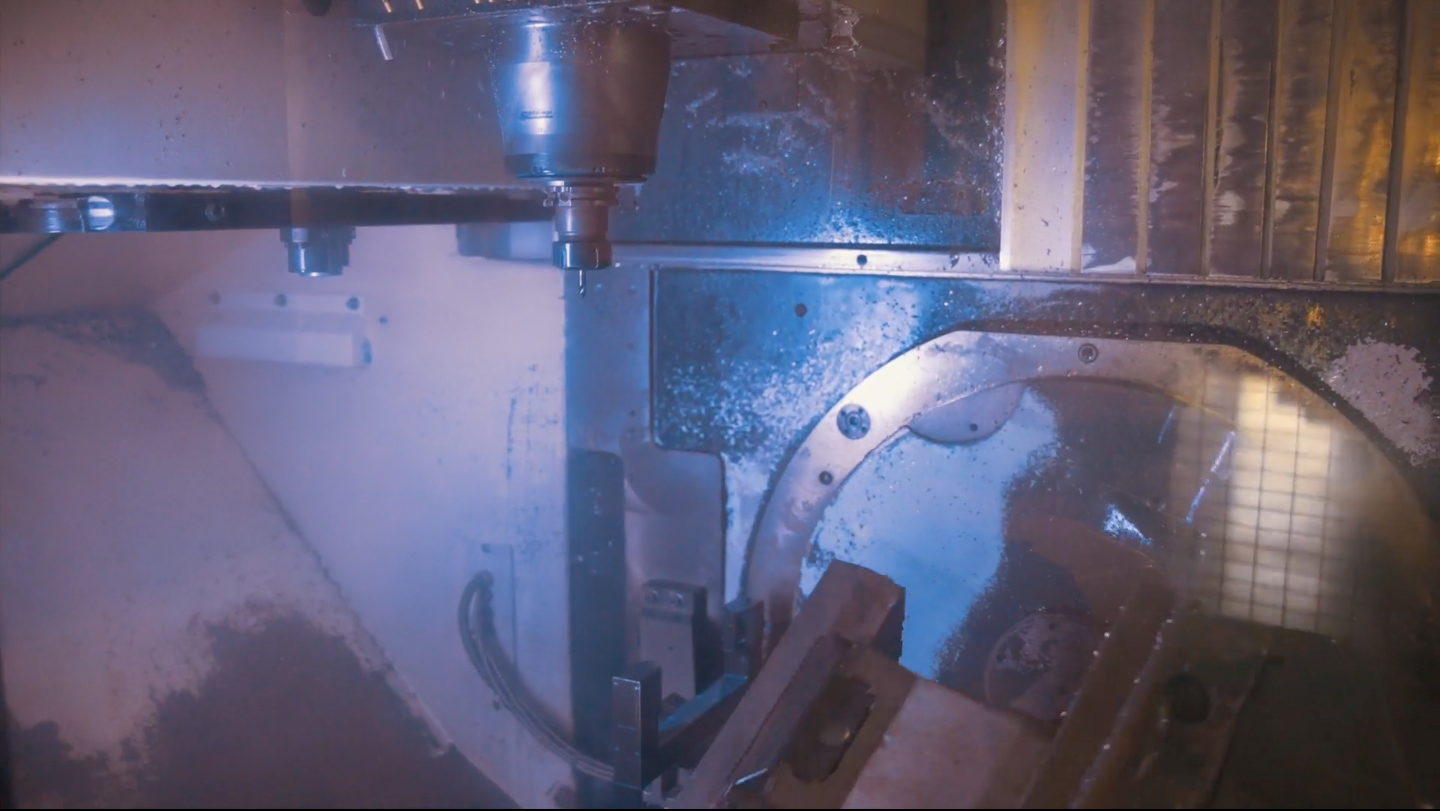

Cutting

Precision is key in cutting, with laser cutting being a popular choice for its accuracy. This step follows the design closely, cutting the metal sheet into required shapes.

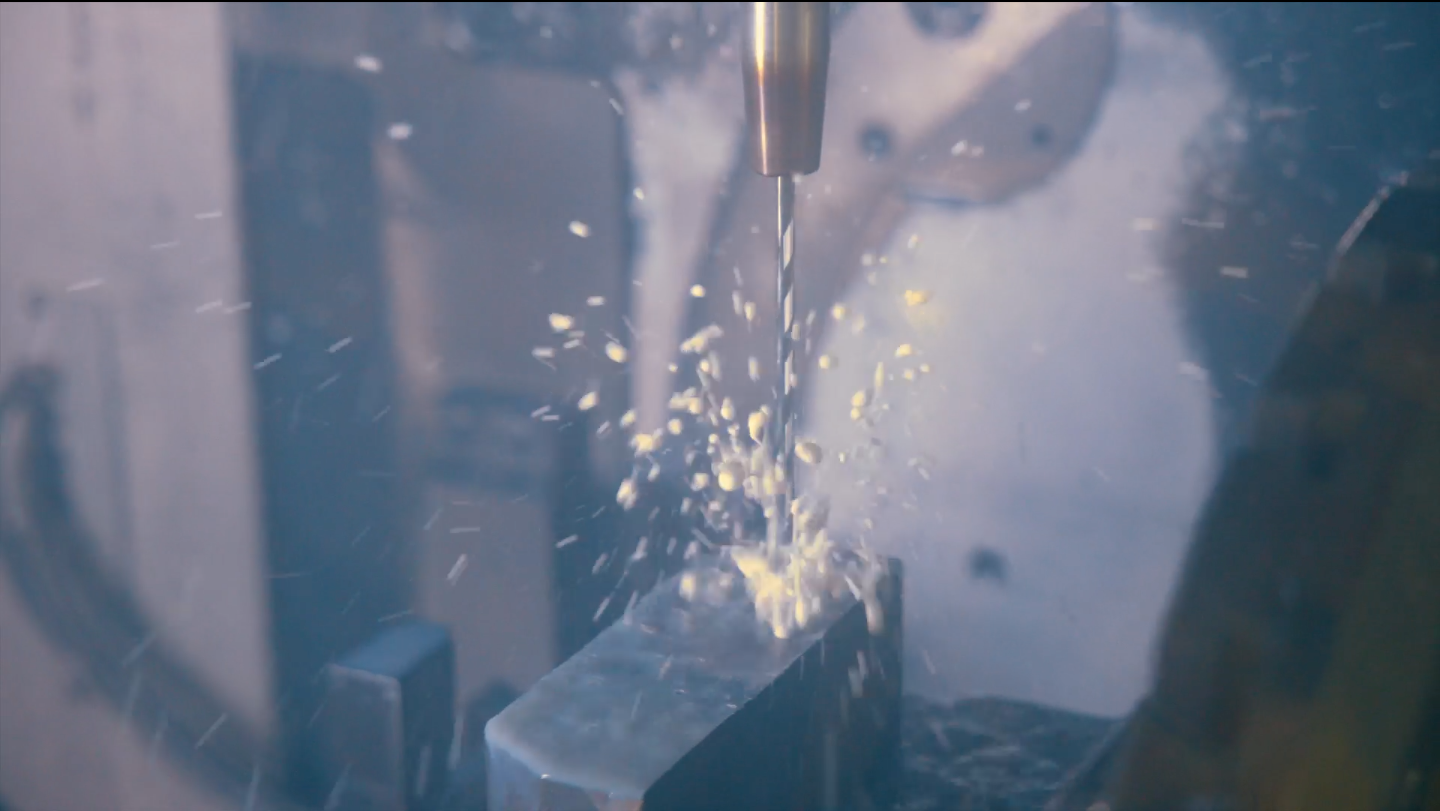

Punching

CNC punching machines play a vital role in shaping the metal by creating perforations or specific forms. This technique is crucial for adding intricate details.

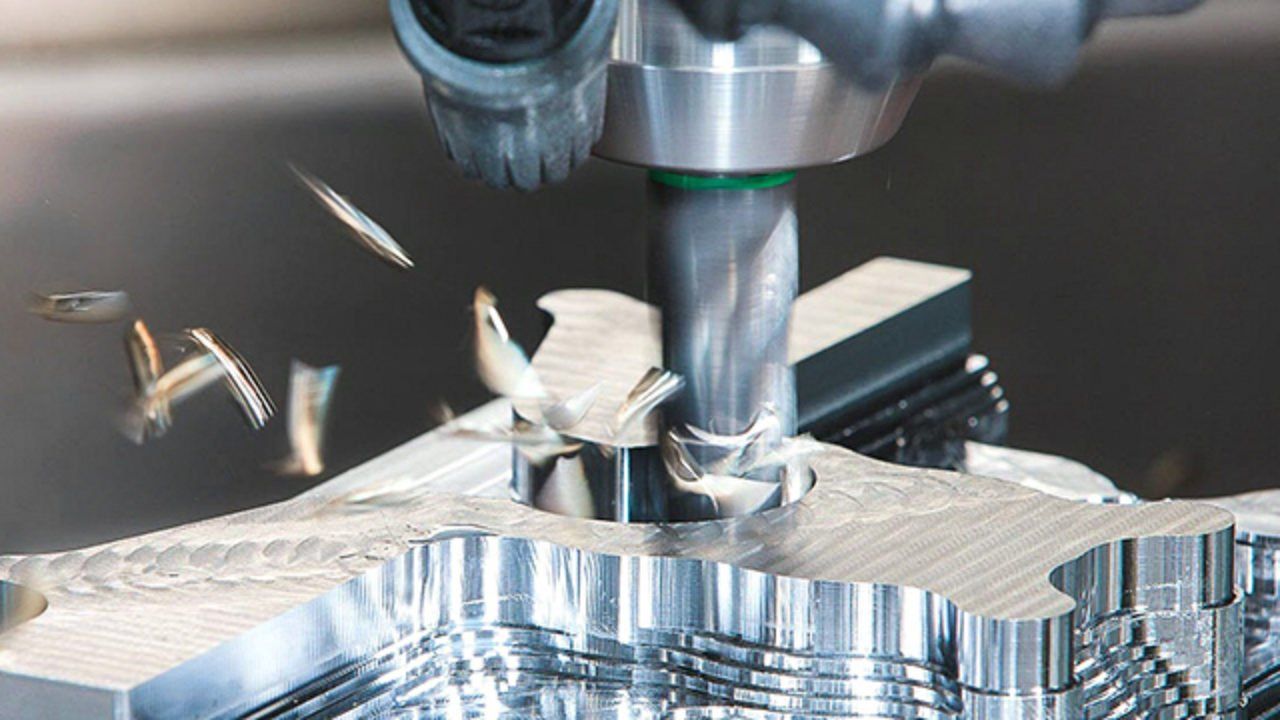

Bending and Forming

Bending, also known as CNC folding, uses various machines to achieve the desired metal curvature. Forming reshapes the metal without reducing its mass, allowing for complex shapes.

Welding

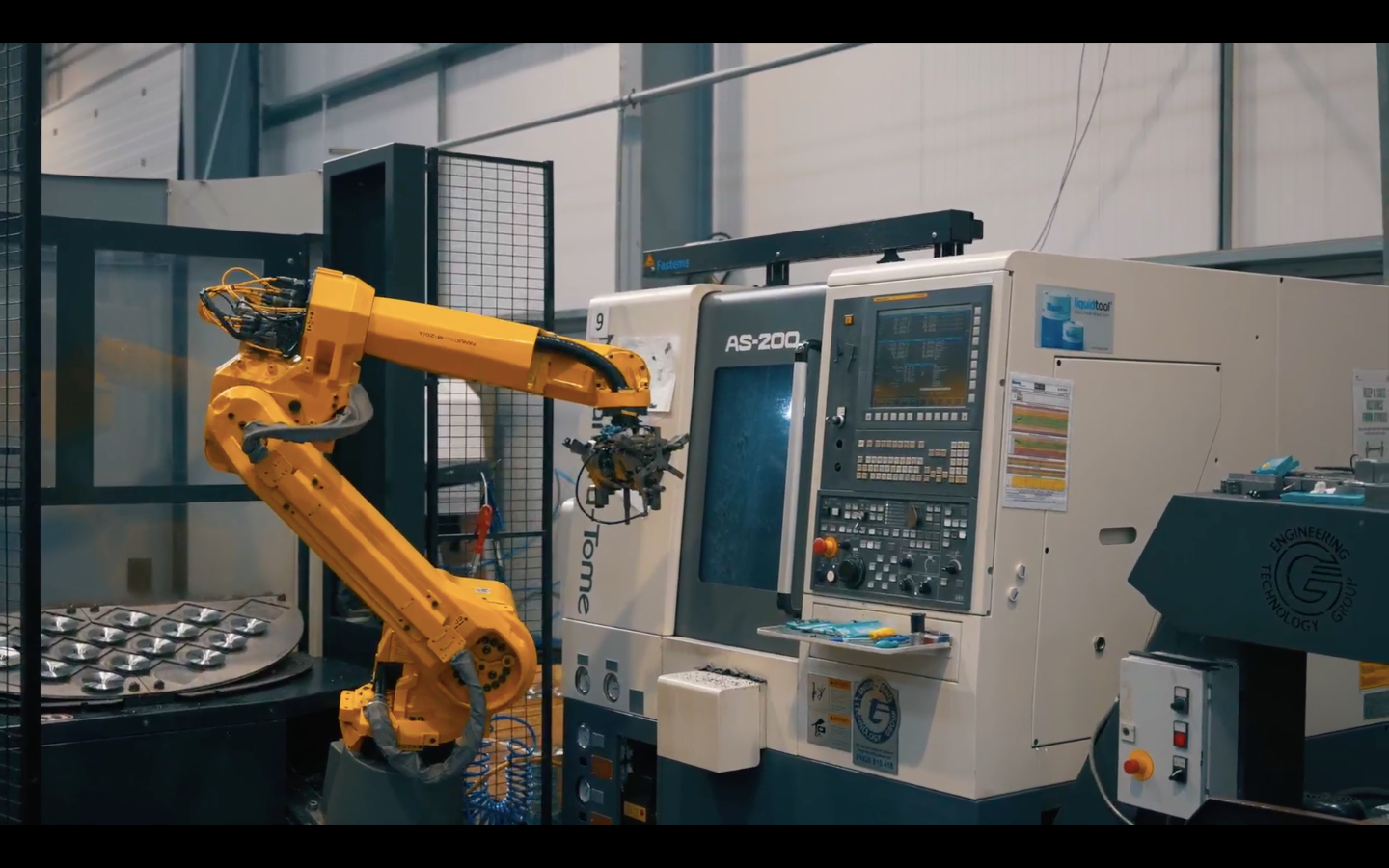

Various welding techniques like MIG, TIG, and robotic welding are employed to assemble the components. This phase is crucial for maintaining the integrity and strength of the final product.

Assembly

The assembly stage can range from simple weld assemblies to complex integrations, including electrical components and other hardware.

Finishing

Finishing includes processes like sandblasting, priming, and painting. This not only enhances the product's appearance but also adds to its durability and corrosion resistance.

Powder Coating

Finally, powder coating involves applying an electrostatic powder and curing at heat to create a durable, aesthetic finish.

Benefits of Sheet Metal Fabrication

Metal sheet fabrication offers numerous benefits:

Durability: Metal structures are known for their long-term durability, resisting wear and tear effectively.

Versatility: This process can produce a wide range of products in various sizes, suitable for many applications.

Maintenance: Metal fabrications are generally resistant to rust, corrosion, fire, and heat, making them low-maintenance and ideal for industrial and commercial use.

Tools and Materials

Key tools in metal sheet fabrication include:

- CAD Design Software

- Laser Cutters

- CNC Punch Machinery

- Bending Machinery

- Robotic Welders

- Powder Coating

These tools ensure precision and quality in the final product.

Materials Used For Metal Sheet Fabrication

Sheet metals play significant roles in various engineering applications, each with distinct properties tailored to specific requirements:

Aluminium

Aluminium is known for its favourable strength-to-weight ratio and high conductivity. This material has extensive use in engineering applications such as automotive components, electrical devices, and precision cooking vessels.

Aluminised Steel

Aluminised steel, formed by combining carbon steel with aluminium, known for its enhanced corrosion resistance. Its application in high-temperature environments, notably kitchen appliances, underscores its resilience and durability.

Carbon Steel

In industrial and consumer markets, carbon steel, through alloying with carbon and subsequent heat treatment, attains heightened hardness and strength. Its versatility makes it a great material choice for a range of products.

Copper

Copper, characterised by superior electrical and thermal conductivity, is a preferred material for engineering applications like sinks, roofs, rain gutters, and doors. Despite its relatively higher cost, its conductivity properties justify its use in specific industries.

Galvanised Steel

Galvanised steel sheets, used in automobile shells, water pipes, fences, roofs, and staircases, derive their corrosion resistance from a zinc coating applied through hot-dipping processes. This enhances their durability in various structural applications.

High-Strength Steel

High-strength steel, fortified through alloying with elements like carbon, manganese, and copper, serves in critical applications such as military armor plates. Its hardness and strength make it a reliable choice for protective components.

Titanium

Titanium, valued for its high strength-to-weight ratio and corrosion resistance, finds application in aerospace engineering for components like aviation parts and medical equipment. Additionally, its recyclability aligns with sustainable engineering practices.

Within engineering, the selection of sheet metals is a meticulous process, considering specific material properties and performance characteristics tailored to the demands of each application. These materials contribute significantly to the diverse landscape of engineering solutions, combining functionality with durability and efficiency.

Each material is chosen based on its specific properties like strength, corrosion resistance, and application suitability, all of which the team at Rotec can advise you on.

Sheet metal fabrication is essential for various applications, ranging from structural and decorative elements to functional components in products across many specialist industries. Sheet metal fabrication merges technical expertise with creativity. You may not realize, but sheet metal fabrication can be seen everywhere such as vehicles to buildings. It’s a skilled engineering process that demonstrates the versatility of metalworking, continually evolving with technological progress.

If you require sheet metal fabrication expertise, our team here at

Rotec Engineering is ready to help. Please

contact us today with your project requirements.