~ A Deep Dive into CNC Machine Tools ~

Each type of CNC machine offers unique capabilities, which allows manufacturers to choose the best fit for their needs.

In today's manufacturing landscape, where precision, efficiency, consistency and flexibility are of utmost importance,

CNC machining is the essential foundation that supports entire industries and enables groundbreaking advancements in fabrication processes. Moreover, the adaptability of CNC machines to various materials, including metals, plastics, and composites, further expands their utility across a wide spectrum of applications.

But, have you wondered about the kind of tools that make this happen and how they work? If yes, then you have come to the right page! In this article, we will explore the various types of CNC machine tools, how they work and their real life applications. But before we dive in, let's briefly look at the history of CNC machining.

The Advent of CNC Machine Tools

CNC machining emerged in the mid-20th century as a response to the growing demand for automated manufacturing processes. Pioneers like John T. Parsons and MIT's Servomechanisms Laboratory laid the groundwork for numerical control systems, leading to the development of the first commercially viable CNC machines in the 1950s and 1960s. Over time, advancements in computer technology and control systems propelled CNC machines from rudimentary beginnings to sophisticated systems capable of handling diverse tasks across industries. Innovators such as Ivan Sutherland and John Runyon further enhanced CNC technology, while companies like Kearney & Trecker Corporation and Cincinnati Milacron drove its commercialization. Initially serving aerospace and defence, CNC machining later expanded into automotive, electronics, and medical device manufacturing, revolutionising production processes and reshaping the modern manufacturing landscape.

What Are CNC Machine Tools?

At its core, a CNC machine tool is a programmable device capable of autonomously executing machining operations with precision and accuracy. Key components of a typical CNC machine include the control unit, which interprets digital instructions (G-code) and coordinates machine movements; the drive system, comprising motors and actuators that translate commands into mechanical motion; the spindle, responsible for rotating cutting tools at high speeds; and the worktable or chuck, which holds the workpiece in place during machining.

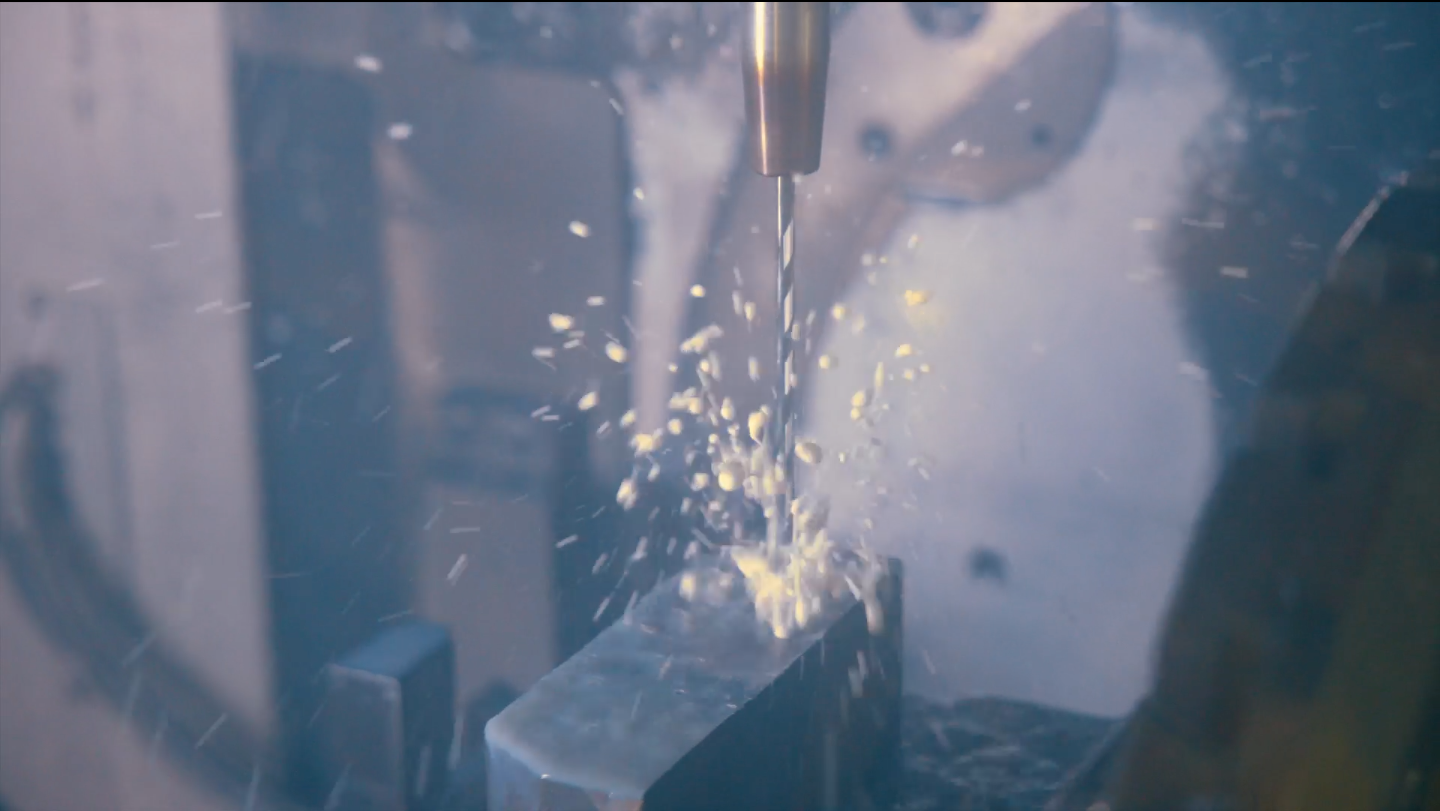

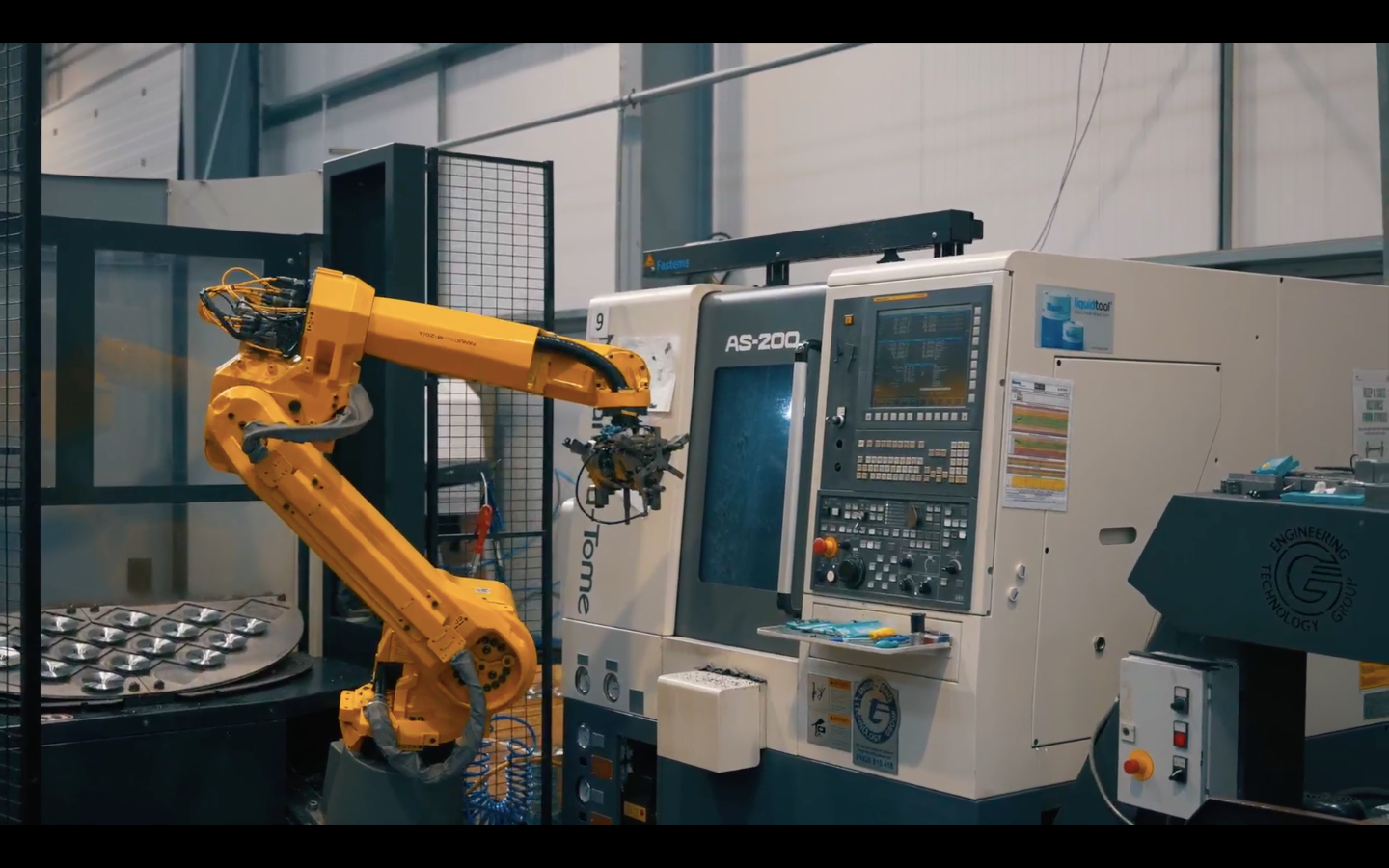

CNC machine tools encompass a diverse array of computer-controlled devices used for subtractive manufacturing processes, including milling, turning, drilling, and grinding. Unlike conventional manual or automated machines, CNC machines operate under the precise command of computer programs, executing intricate designs with unparalleled accuracy and repeatability. Their significance lies in their ability to revolutionise production workflows, enabling manufacturers to create complex parts with minimal human intervention while achieving tight tolerances and high-quality finishes.

Operating Principles and Mechanics of CNC Machine Tools

CNC machines operate on the principle of Cartesian coordinates, using X, Y, and Z axes to define the position and movement of cutting tools relative to the workpiece. The control unit translates instructions from a pre-programmed code into electrical signals, which activate the drive system to move the machine along predetermined paths. By precisely controlling spindle speed, feed rate, and tool engagement, CNC machines can perform a wide range of machining operations, including milling, turning, drilling, and grinding, with exceptional precision and repeatability.

Varieties of CNC Machine Tools

CNC machine tools come in various configurations and designs tailored to specific machining tasks and industries. Common types of CNC machines include vertical and horizontal milling machines, which use rotating cutting tools to remove material from a workpiece; CNC lathes, which rotate cylindrical workpieces against fixed cutting tools to produce symmetrical parts; CNC routers, which utilise high-speed spindles and interchangeable cutting bits to carve intricate designs into wood, plastic, and other materials; and CNC grinders, which employ abrasive wheels to achieve fine surface finishes and tight tolerances on hardened materials. Each type of CNC machine offers unique capabilities and advantages, allowing manufacturers to select the most suitable equipment for their application requirements and production goals.

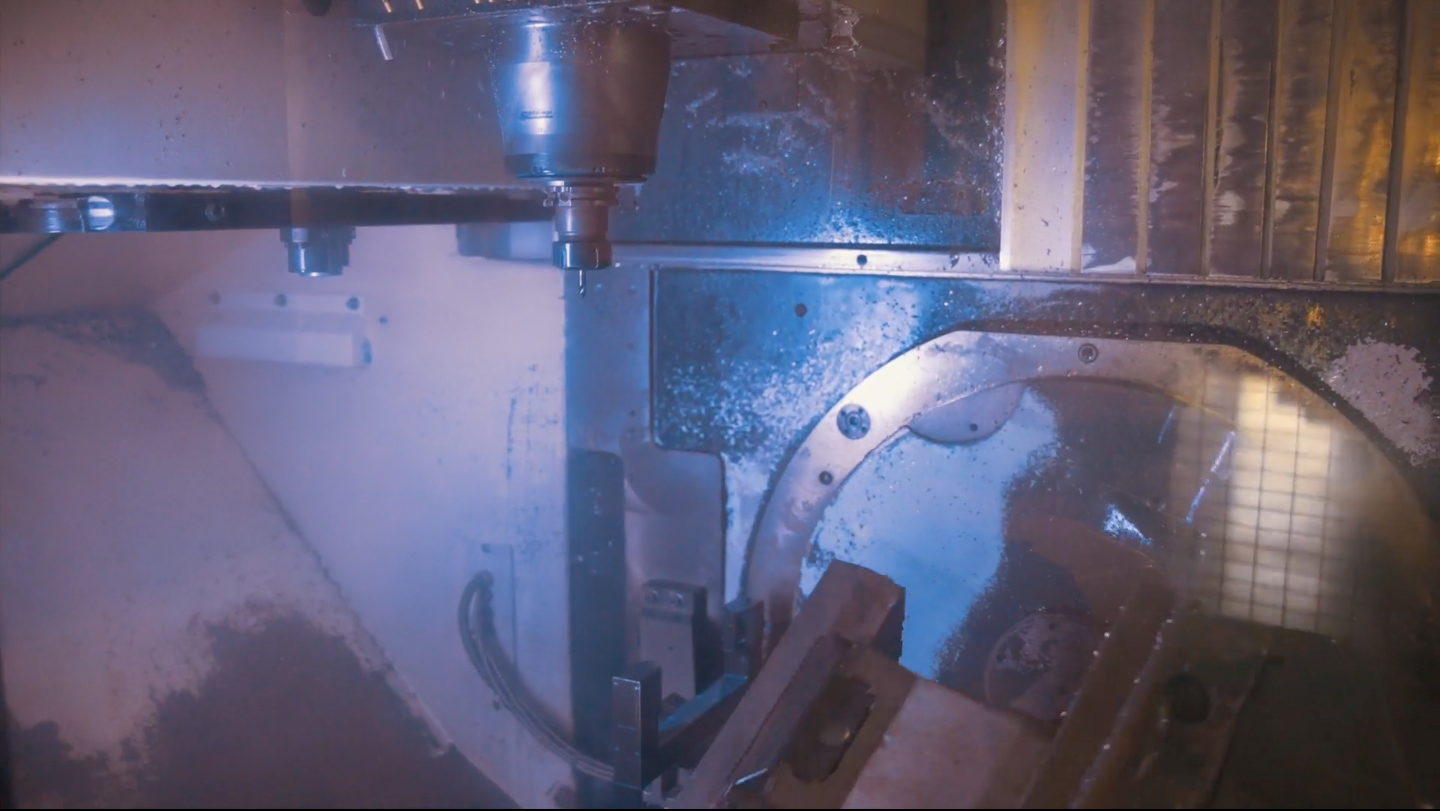

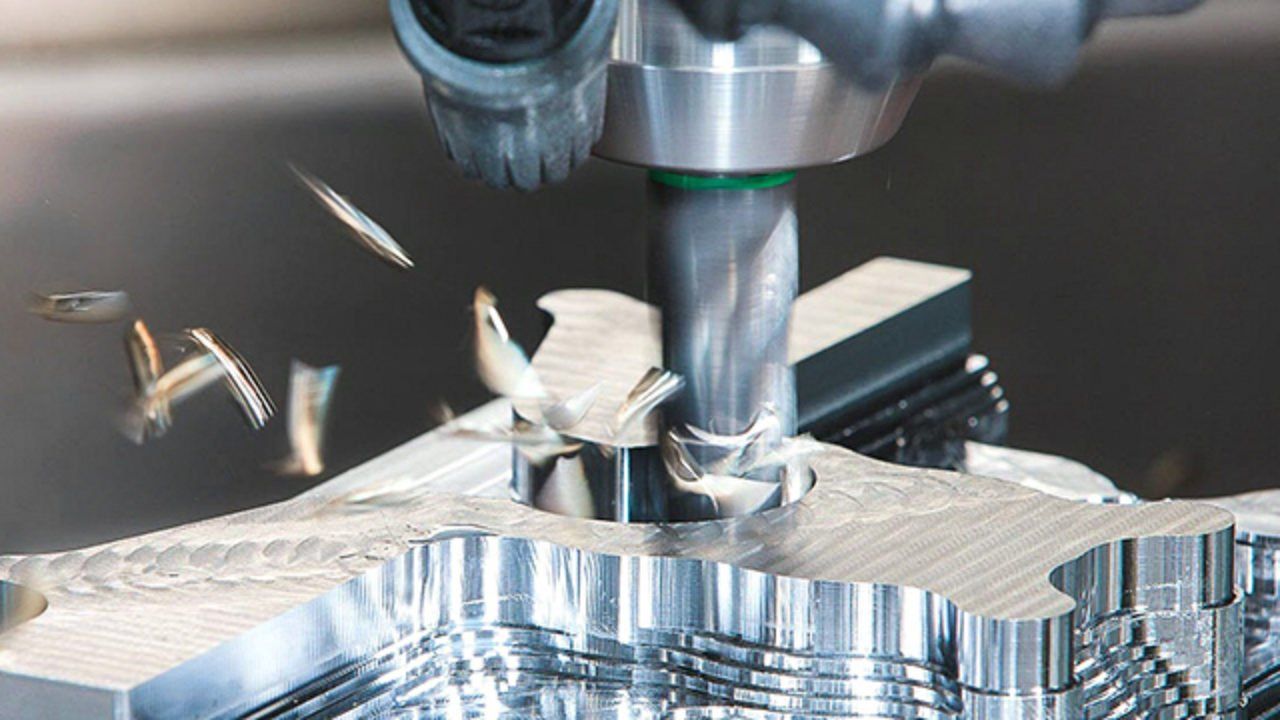

CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece, producing complex shapes, contours, and features with high precision. They are versatile machines capable of performing a wide range of milling operations, including face milling, end milling, slotting, and contouring.

Types of CNC Milling Machines:

- Vertical Milling Machines: In vertical milling machines, the spindle axis is vertically oriented, allowing for easy positioning of the workpiece and tool changes. They are commonly used for machining flat surfaces, pockets, and slots.

- Horizontal Milling Machines: Horizontal milling machines have a horizontally oriented spindle, with the workpiece positioned on a horizontal table. They are ideal for heavy-duty machining and production of large components.

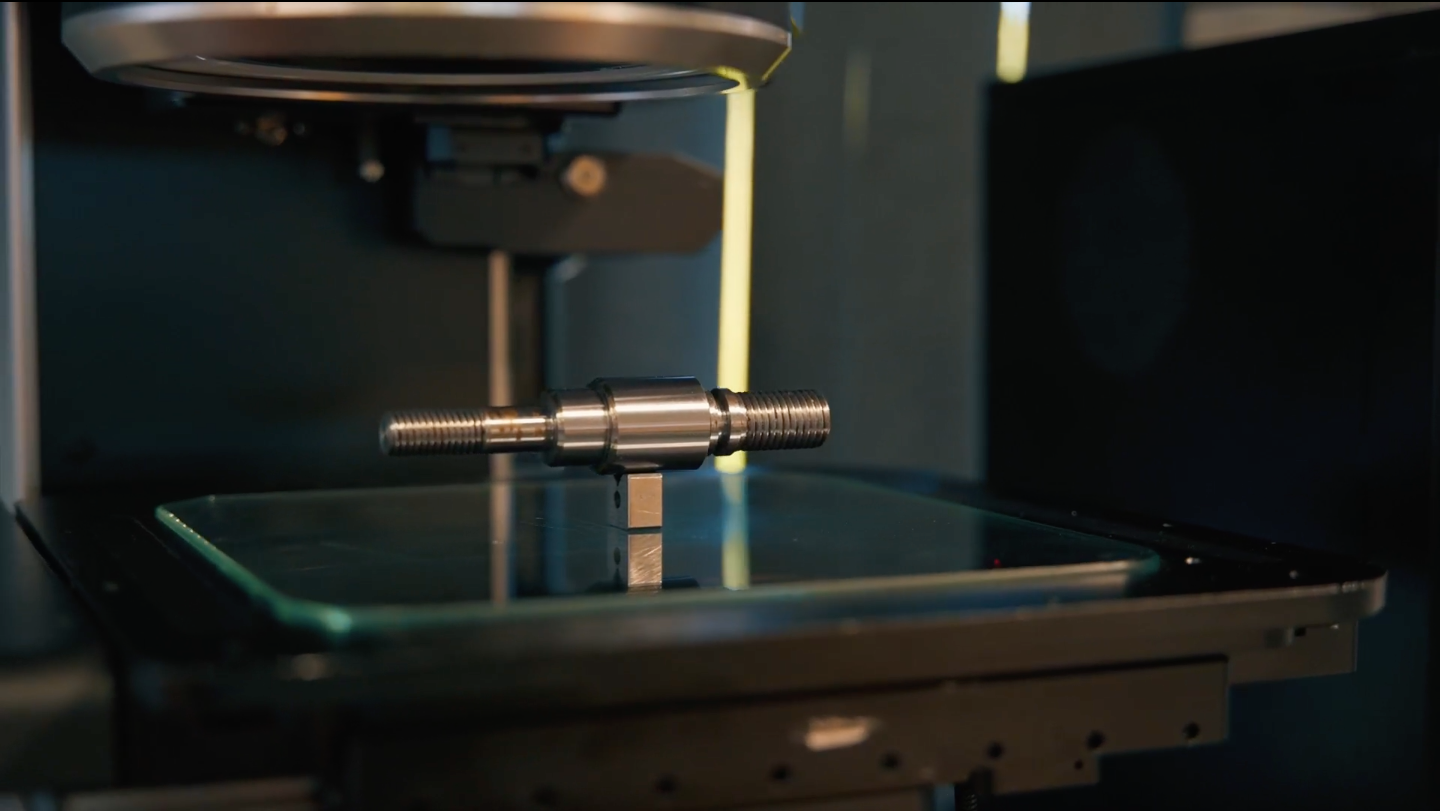

CNC Lathes

CNC lathes rotate cylindrical workpieces while cutting tools are held stationary, allowing for the production of symmetrical parts such as shafts, cylinders, and cones. They are widely used in the production of precision components for automotive, aerospace, and medical applications.

Types of CNC Lathes:

- 2-Axis Lathes: These lathes feature two axes of movement – X and Z – allowing for turning, facing, and drilling operations.

- Multi-Axis Lathes: Multi-axis lathes can have additional axes, such as live tooling (Y-axis), allowing for complex machining operations, including milling, drilling, and tapping in a single setup.

CNC Routers

CNC routers utilise high-speed spindles and interchangeable cutting bits to carve intricate designs into various materials, including wood, plastic, foam, and composite materials. They are commonly used in woodworking, cabinetry, signage, and prototyping applications.

Types of CNC Routers:

- 3-Axis Routers: These routers move along three axes – X, Y, and Z – allowing for flat surface machining and basic 3D contouring.

- 4-Axis and 5-Axis Routers: These routers add additional rotational axes (typically A and B axes) to the basic 3-axis setup, enabling more complex machining operations and the production of highly detailed 3D shapes and sculptures.

CNC Grinders

CNC grinders use abrasive wheels to remove material and achieve precise surface finishes on hardened materials such as metals and ceramics. They are essential for producing high-precision components with tight tolerances in industries such as aerospace, automotive, and toolmaking.

Types of CNC Grinders:

- Surface Grinders: Surface grinders are used to produce flat surfaces and achieve smooth finishes on workpieces. They utilise a horizontal grinding wheel to remove material from the surface of the workpiece.

- Cylindrical Grinders: Cylindrical grinders are used to machine cylindrical or tapered surfaces on workpieces. They feature a rotating grinding wheel that traverses along the length of the workpiece to remove material and achieve the desired shape.

Each type of CNC machine tool offers unique capabilities and advantages, allowing manufacturers to select the most suitable equipment for their specific application requirements and production goals. Additionally, advancements in CNC technology, such as multi-axis machining and hybrid machines combining milling and turning capabilities, continue to expand the capabilities and versatility of CNC machine tools, driving innovation in precision manufacturing.

Advantages of CNC Machine Tools

1. Precision and accuracy

CNC machine tools excel in delivering unparalleled precision and accuracy in machining operations. By eliminating the potential for human error associated with manual machining, CNC machines ensure consistent part dimensions and surface finishes, meeting tight tolerances with remarkable reliability. This precision is crucial in industries such as aerospace, automotive, and medical, where even minor deviations can lead to significant performance issues or product failures.

2. Increased productivity and efficiency

Automation is a hallmark feature of CNC machine tools, enabling continuous operation without the need for constant human supervision. As a result, CNC machines can operate 24/7, maximising production throughput and minimising idle time. Additionally, CNC programming allows for optimised tool paths and cutting strategies, reducing cycle times and material waste compared to conventional machining methods. The combination of automation and efficiency makes CNC machining a cost-effective solution for high-volume production runs.

3. Flexibility and versatility

One of the key advantages of CNC machine tools is their ability to adapt to a wide range of machining tasks and part geometries. With the ability to change cutting tools and reprogram machine parameters rapidly, CNC machines can produce diverse components with minimal setup time. This flexibility is invaluable in job shops and contract manufacturing environments, where the ability to accommodate varying customer demands and part specifications is essential for business success.

4. Automation and reduced labour costs

By automating machining processes, CNC machine tools reduce the reliance on manual labour, thereby minimising labour costs and mitigating the effects of skilled labour shortages. Operators oversee machine operation, monitor quality, and perform maintenance tasks, but the need for manual intervention during production is significantly reduced. This not only improves workforce efficiency but also enhances workplace safety by minimising exposure to hazardous machining environments.

Applications Across Industries

1. Automotive and aerospace

- CNC machining is crucial for producing precise components in the automotive and aerospace sectors.

- Used for engine parts, transmission components, aircraft structures, and turbine blades.

- Enables fabrication of complex moulds, dies, and tooling for manufacturing.

2. Electronics and consumer goods

- CNC machining employed for intricate component production in electronics and consumer goods.

- Capable of machining plastics, metals, and composites for various applications.

- Used in manufacturing smartphone casings, computer peripherals, and home appliances.

3. Medical and healthcare

- CNC machining essential for manufacturing medical devices, implants, and prosthetics.

- Ensures precision and quality for patient safety and treatment efficacy.

- Used in producing surgical instruments, orthopaedic implants, and dental prosthetics.

4. Defence and military

CNC machining is critical for producing mission-critical components and equipment.

Enables rapid prototyping, production, and maintenance of defence equipment.

Ensures adherence to military specifications and standards for quality and performance.

5. Precision Engineering and Toolmaking

- CNC machining is crucial for producing precision tools, dies, moulds, and fixtures.

- Ensures quality and consistency in various manufacturing processes.

- Contributes to efficiency and reliability of manufacturing operations.

6. Prototyping and Rapid Manufacturing

- CNC machining widely employed for quick and cost-effective production of prototypes.

- Enables rapid iteration of designs and production of high-quality parts.

- Used for testing and validating concepts before full-scale production.

7. Customization and Personalization

- CNC machining enables customization and personalization of products.

- Capable of engraving, embossing, and etching intricate designs onto various materials.

- Enhances brand loyalty and customer satisfaction in competitive markets.

8. Energy and Renewable Resources

- CNC machining vital for fabricating components for renewable energy systems.

- Ensures optimal performance and reliability of wind turbines, solar panels, etc.

- Employed in manufacturing components for oil and gas exploration and refining.

9. Research and Development

- CNC machining supports research efforts across scientific and engineering disciplines.

- Used for fabricating custom components, prototypes, and experimental setups.

- Advances scientific knowledge in fields like materials science and biomechanics.

10. Art, Architecture, and Design

- CNC machining increasingly utilised in artistic, architectural, and design contexts.

- Enables creation of intricate sculptures, installations, furniture, and architectural elements.

- Pushes boundaries of creativity and expression in visual arts and architecture.

Final Thoughts

As technology continues to advance and new applications emerge, the role of CNC machine tools in shaping the future of manufacturing is poised to expand, ushering in a new era of precision engineering and industrial excellence.

In an era defined by precision and innovation, your manufacturing needs demand a partner capable of delivering exceptional results. At Rotec, we specialise in complex CNC machining, leveraging cutting-edge technology and decades of expertise to bring your most intricate designs to life with unparalleled accuracy and efficiency. Whether you're in aerospace, automotive, healthcare, or any other industry requiring precision engineering solutions, we stand ready to meet your unique challenges and exceed your expectations.

Contact us today to discover how we can elevate your manufacturing capabilities and support your success in an increasingly competitive marketplace!